Cable and rigid control systems maintenance

WARNING

includes inspection to discover actual and potential

Your bare hands should NEVER be used to

defects, servicing with lubricants, and correction of

check for broken wires. Using your bare hands to

reported malfunctions and defects. Malfunctions that

check for broken wires could result in personal

occur in control systems include frayed and loosened

injury.

bearings, unnatural tightness (binding), and broken or

damaged components.

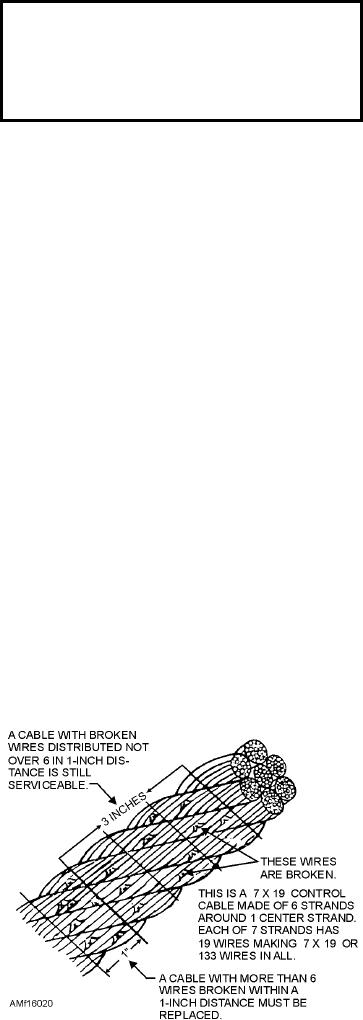

Tests have proven that control cables may have

CABLE CONTROL SYSTEM

broken wires and still be capable of carrying their

designated load. However, any 7 x 19 cable that shows

Cables have many advantages. They will not sever

more than six broken wires in any 1-inch length, or any

readily under sudden strains. Cables are stronger than

7 x 7 cable that shows more than three broken wires in

any 1-inch length, must be replaced. A maximum of

steel rods or tubing of the same size. They flex without

three broken wires per inch is allowable in the length of

setting (permanent deformation) and can be led easily

cables passing over pulleys, drums, or through

around obstacles by using pulleys. Cables can be

fairleads. Figure 16-20 shows how to determine if a

installed over long distances (such as in large aircraft)

cable is serviceable.

without a great degree of sagging or bending. Vibration

will not cause them to harden, crystallize, or break, as

Corrosion, kinking, and excessive wear should be

given particular attention during cable inspection. If a

may be the case with push-pull control rods. Because

cable is found to be kinked or badly worn, it should be

of the great number of wires used in cables, cable

replaced, even though the number of broken wires is

failure is never abrupt, but is progressive over periods

less than that specified for replacement. If the surface

of extended use. When used for the manipulation of a

of the cable is corroded, relieve the tension on the cable

unit in a control system, they are usually worked in

and carefully untwist it to visually inspect the interior.

pairs-one cable to move the unit in one direction, the

Any corrosion on the interior strands of the cable

other to move it in the opposite direction. Weight is

constitutes failure, and the cable must be replaced. If

saved in spite of a second cable because the push-pull

no internal corrosion is detected, remove loose,

rod needed to cause a similar movement in a unit would

external corrosion with a clean, dry rag or fiber brush

have to be quite thick and heavy (comparatively

and apply the specified preservative compound.

speaking). Since cables are used in pairs and are

NOTE: Do not use metal wool or solvents to clean

stretched taut, very little play is present in system

installed cable. Metal wool will embed tiny dissimilar

controls, and no lost motion exists between the

metal particles and create further corrosion problems.

a c t u a t i n g d ev i c e a n d t h e u n i t . C o n s e q u e n t l y,

The use of solvents will remove the internal cable

cable-controlled units respond quickly and accurately

lubricant and allow the cable strands to abrade and

to cockpit control movement. In some simple cable

further corrode.

systems, only one cable is used, and a spring provides

the return action.

Cable Maintenance

Cable control systems require more maintenance

than rigid linkage systems; therefore, they must be

inspected more thoroughly. Cables must be kept clean

and inspected periodically for broken wires, corrosion,

kinking, and excessive wear.

INSPECTION.--Broken wires are most apt to

occur in lengths of cable that pass over pulleys or

through fairleads. On certain periodic inspections,

cables are checked for broken wires by passing a cloth

along the length of the cable. Where the cloth snags the

cable is an indication of one or more broken wires.

Figure 16-20.--Determining serviceable cable.

16-24