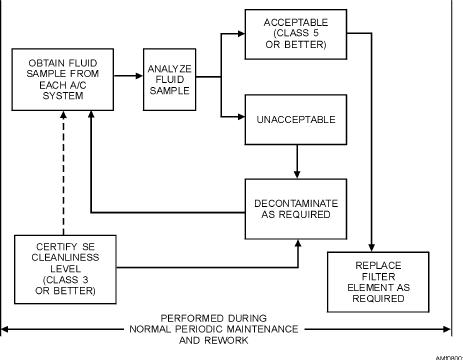

Figure 8-1.--Periodic fluid surveillance requirements.

is not taken, the complete system could be con-

MAINTENANCE PROCEDURES

taminated. Hydraulic systems and components are

The general contamination control procedures and

serviced by using approved fluid dispensing equipment

testing of hydraulic systems, subsystems, components,

only. Unfiltered hydraulic fluid should NEVER be

and fluids are requirements for each maintenance level.

introduced into systems or components.

Hydraulic fluid contamination controls ensure the

All portable hydraulic test stands must receive the

cleanliness and purity of fluid in the hydraulic system.

required periodic maintenance checks. Make certain

Fluid sampling and analysis is performed periodically.

that each unit is approved, and the applicable MIM is

Checks are made sufficiently before the scheduled

readily accessible and up to date. When the portable

aircraft induction date so that if fluid decontamination

hydraulic test stand is not in use, it should be protected

is required, it may be accomplished at that time. The

against contaminants such as dust and water. You

condition of the fluid depends, to a large degree, on the

should ensure that correct hoses are used on each stand,

condition of the components in the system. If a system

and that they are approved for the type of fluid being

requires frequent component replacement and

used. Properly cap hoses when they are not being used.

servicing, the condition of the fluid deteriorates

Hoses must be serialized and must remain with the

proportionately.

equipment. Make sure the hoses are coiled, kept free of

Replacement of aircraft hydraulic system filter

kinks, and properly stowed. Make sure they are in

elements takes place on a scheduled or conditional

satisfactory condition and are checked periodically.

basis, depending upon the requirements of the specific

Replace any hose that exhibits fluid seepage from the

system. A differential pressure flow check and bubble

outer cover or separation between the inner tube and the

point test are performed to properly evaluate the

outer cover. Portable hydraulic test stands that show

condition of a cleanable filter element. These two

indications of contamination or that have loaded

checks are done to verify that the element is good

(clogged) filters are removed from service im-

before it is installed in a system or component. Many

mediately and returned to the supporting activity for

filter elements look identical, but not all of them are

maintenance.

compatible with flow requirements of the system.

Use only approved lubricants for O-ring seals;

If the hydraulic system fluid is lost to the point that

incorrect lubricants will contaminate a system. Many

the hydraulic pumps run dry or cavitate, you should

lubricants look alike, but few are compatible with

change the defective pumps, check filter elements, and

hydraulic fluids. The only approved O-ring seal

decontaminate the system as required. Check the

lubricants are hydraulic fluid MIL-H-5606, hydraulic

applicable MIM for corrective action to be taken

fluid MIL-H-83282, hydraulic fluid MIL-H-46170, or

regarding decontamination of the system. If this action

a thin film of grease, MIL-G-81322.

8-3