Contaminants in hydraulic fluids are classified as

particulate and fluid contamination. They may be

further classified according to their type, such as

organic, metallic solids, nonmetallic solids, foreign

fluids, air, and water.

PARTICULATE CONTAMINATION

The type of contamination most often found in

aircraft hydraulic systems consists of solid matter. This

type of contamination is known as particulate

contamination.

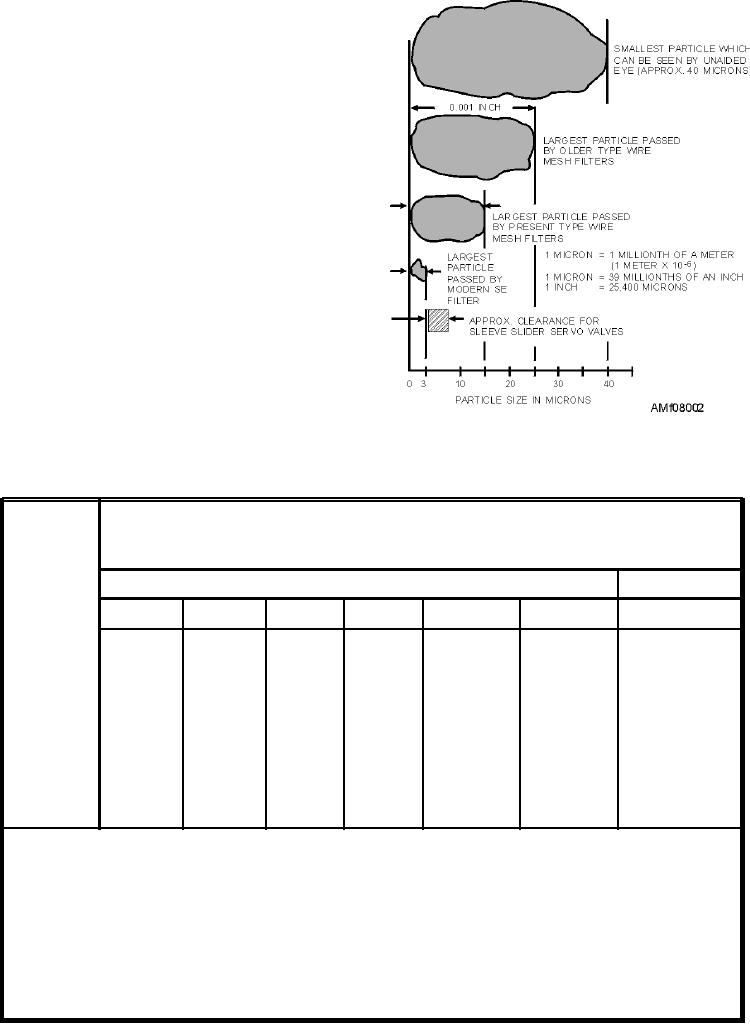

The size of particulate matter in hydraulic fluid is

measured in microns (millionths of a meter). The

largest dimensions (points on the outside of the

particle) of the particle are measured when determining

its size. The relative size of particles, measured in

microns, is shown in figure 8-2. Table 8-1 shows the

various classes of particulate contamination levels.

Contamination of hydraulic fluid with particulate

matter is a principal cause of wear in hydraulic pumps,

actuators, valves, and servo valves. Spool-type electro

Figure 8-2.--Graphic comparison of particle sizes.

Table 8-1.--Particle Contamination Level By Class

MICRON

SIZE

PARTICLE CONTAMINATION LEVEL--BY CLASS

RANGE

Acceptable

Unacceptable

0

1

2

3

5

6

4

5-10

2,700

4,600

9,700

24,000

32,000

87,000

128,000

10-25

670

1,340

2,680

5,360

10,700

21,400

42,000

25-50

93

210

380

780

1,510

3,130

6,500

50-100

16

28

56

110

225

430

1,000

Over 100

1

3

5

11

21

41

92

_______

_______

_______

_______

_________

_________

__________

Total

3,480

6,181

12,821

30,261

44,456

112,001

177,592

NOTES

1. The class of contamination is based upon the total number of particles in any size range per 100 ml of

hydraulic fluid. Exceeding the allowable particle count in any one or more size ranges requires that the

next higher class level be assigned.

2. Class 5 is the maximum acceptable contamination level for hydraulic systems in naval aircraft. Fluid

delivered by SE to equipment under test or being serviced must be Class 3, or cleaner.

3. The Class 5 level of acceptability shall be met at the inspection interval specified for the equipment

under test.

8-5