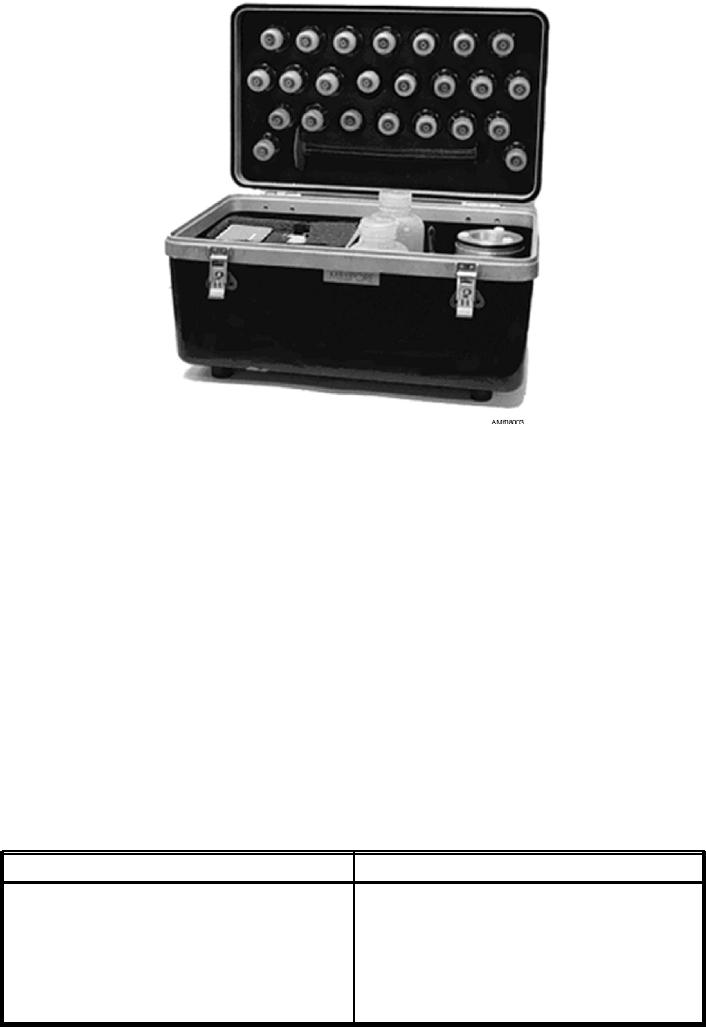

Figure 8-3.--P/N57L414 contamination analysis kit.

membrane discoloration correlates to a level of

PATCH TESTING

particulate contamination. By visually comparing the

Patch testing is the primary contamination mea-

test filter with contamination standards that represent

surement method used at all levels of maintenance. The

known contamination levels, the contaminant level of

P/N57L414 contamination analysis kit (fig. 8-3) is used

the system can be determined.

to perform patch testing. In the patch test method, a

Accurate determination of hydraulic contaminant

fluid sample of known volume is filtered through a filter

levels requires proper sampling techniques, using

membrane of known porosity. When the fluid passes

equipment and materials that are known to be clean. If

through the filter, all particulate matter in excess of a

you allow any foreign matter to contaminate the sample

size determined by the filter characteristics is retained

fluid or testing equipment, the results will be wrong.

on the surface of the membrane. The retention of par-

The operational procedures discussed in the

ticulate matter causes the membrane to discolor propor-

following paragraphs are general in nature. For specific

tionally to the particulate level of the fluid sample. Free

information on the use of contamination analysis kits,

water will appear either as droplets during the fluid

you should refer to NAVAIR 01-1A-17 and NAVAIR

sample processing or as a stain on the test filter.

17-15E-52. Table 8-2 lists the materials required to

The typical color of contamination in any given

perform the analysis.

system is usually uniform. The degree of filter

Table 8-2.--Materials Required for Contamination Analysis

Material

Specification/P/N

Dry Cleaning Solvent

MIL-PRF-680, Type II

Wiping Cloths, disposable

Can, Metal, 1 gallon

Can, Safety, 5 gallon

RR-S-30

Kit, Hydraulic Fluid Contamination Analysis

P/N 57L414

8-9