Q8-14.

What is the primary contamination measure-

The difference is caused by the particle counter not

ment method used at all levels of mainte-

counting those particles smaller than 5 microns, while

nance?

many of them are retained by the patch-test filter

membrane, causing it to discolor proportionately.

Q8-15.

When is the best time to take a hydraulic fluid

When test results conflict, the equipment tested is

sample?

considered unacceptable if it fails either test method.

Q8-16.

Before taking a hydraulic fluid sample from a

The equipment should then be subjected to

hydraulic test stand, you must recirculate the

decontamination.

fluid for how long?

You need to recognize that the differing test results

Q8-17.

How many samples should you take from each

may indicate system deficiencies and justify a request

sampling point?

for an engineering investigation of the equipment. Poor

correlation between particle counts and patch tests can

Q8-18.

When sampling hydraulic fluid, what size test

result from improper sample-taking procedures,

filter should you use?

incorrect particle counter calibration, or faulty test

procedures. These possibilities must be carefully

DECONTAMINATION

investigated if a correlation problem is encountered.

LEARNING OBJECTIVE: Identify de-

HALOGEN TESTING

contamination methods used on naval aircraft

and their purpose.

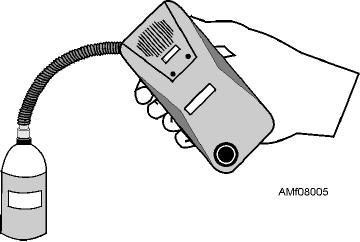

The halogen leak detector (fig. 8-5) is used to test

System decontamination is a maintenance opera-

hydraulic fluid samples for MIL-C-81302A (Freon) or

tion performed when a system contains fluid that is

other chlorinated solvents. The detector is a

unacceptable because of contamination. The fluid may

battery-powered, self-contained instrument. The in-

be contaminated with foreign matter or it is not

strument provides an audible indication, varying from a

considered acceptable for service for some other

slow ticking sound to a loud squeal, to indicate the level

reason. The purpose of decontamination is to remove

of the vapor concentration.

foreign matter from the operating fluid or to remove the

You can determine the acceptability of unknown

contaminated fluid itself. Before you can de-

hydraulic fluid samples by using the HDL-440 leak

contaminate an affected system, replace any failed or

detector. To do this, you compare the vapor level of a

known contamination-generating components. Other

known hydraulic fluid to that of the unknown hydraulic

components of the system are not to be disturbed,

fluid and determine whether the unknown sample

unless required.

contains more or less than 200 ppm (parts per million)

of chlorinated solvents. The calibration standard used

METHODS

in the HDL-440 is hydraulic fluid MIL-H-5606 or

MIL-H-83282, which contains a known amount

There are four basic methods used to de-

(200 ppm) of MIL-C-81302.

contaminate aircraft hydraulic systems. The methods

are recirculation cleaning, flushing, purging, and

Recirculation Cleaning

Recirculation cleaning is a decontamination

process in which the system to be cleaned is powered

from a clean external power source. The system is

cycled so it produces a maximum interchange of fluid

between the powered system and the SE used to power

it. When decontaminating a system, the contaminated

fluid is circulated through the hydraulic filters in the

aircraft system and in the portable hydraulic test stands.

Decontamination that uses the recirculation

cleaning method is a filtration process. It can remove

Figure 8-5.--HDL-440 halogen leak detector in operation.

8-14