Use recirculation cleaning to remove excessive

only that foreign matter that is retained by the filter

particulate matter that results from normal component

elements normally found in the equipment. A key

wear, limited component failure, or external sources.

factor in recirculation cleaning is the use of

Clean the system by powering it with an external

high-efficiency, 3-micron (absolute) filter elements.

portable hydraulic test stand. Operate the aircraft

Absolute filter elements have no fluid bypass when the

systems so maximum interchange of fluid is produced

filter clogs. The filters have a large dirt-holding

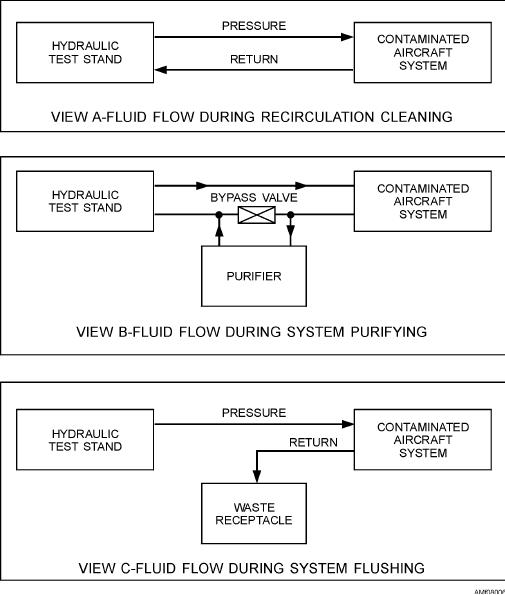

between the aircraft and the test stand. View A of figure

capacity in the portable test stands used for this

8-6 shows a flow diagram for recirculation cleaning.

purpose. In a single fluid pass, these filters remove all

particulate matter larger than 3 microns, and a high

Test stands used for recirculation cleaning must be

percentage of the other particles down to submicron

equipped with 3-micron (absolute) filtration. Before

size. Recirculation cleaning is effective in removing

connecting the test stand to the aircraft, the stand itself

hard particulate matter from hydraulic fluid that is

must be recirculation cleaned and deaerated, and its

otherwise serviceable. It must be recognized that the

contamination level verified to meet the Navy Standard

filters are not capable of removing water, other foreign

Class 3 cleanliness level. If the system has a makeup

fluids, or dissolved solids. Therefore, recirculation

reservoir, drain and reservice the system reservoir prior

cleaning is limited to decontamination of systems

to recirculation cleaning. Makeup reservoirs have a

found to have a particulate level in excess of Navy

single fluid port similar to an accumulator; therefore,

Standard Class 5, whose fluid is considered otherwise

little or no fluid exchange takes place during

acceptable. For specific procedures on recirculation

recirculation cleaning.

cleaning, you should refer to the applicable MIM.

Figure 8-6.--Fluid flow during decontamination.

8-15