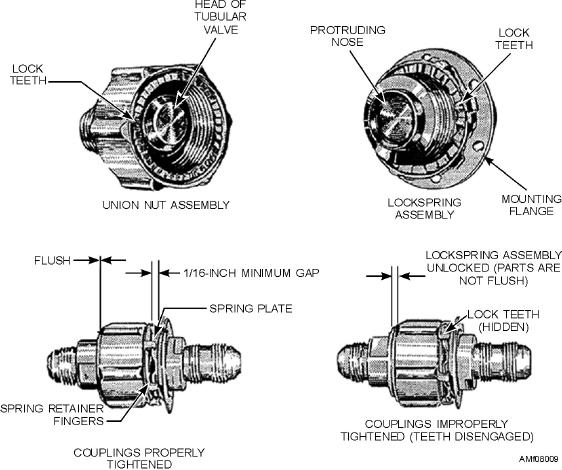

of the S1 half. Simultaneously, the head of the tubular

All parts referred to in the following paragraphs are

valve (1) contacts the face of the poppet valve (7), thus

identified in figure 8-8. The two halves of the coupling

preventing air from entering the system.

may be connected by placing the tubular valve (1)

within the protruding nose (6) of the mating half, and

Tightening the union nut pulls the coupling halves

rotating the union nut in a clockwise direction. The

together. This causes the nose of the S4 half to push the

union nut must be rotated until its teeth (5) fully engage

sleeve into the S1 half, uncovering the ports to the

the lock spring (8). A properly tightened coupling will

tubular valve. At the same time, the head of the tubular

have compressed the lock spring until a 1/16-inch

valve depresses the poppet valve.

minimum gap exists between the inside lip of the spring

When the coupling halves are fully connected, the

retainer fingers and the spring plate. Figure 8-9 shows

sleeve and poppet valve have reached the positions

the coupling both properly connected and improperly

shown in the left-hand view of figure 8-9. The nose of

connected.

the S4 half has engaged the O-ring packing of the S1

The locking action may be followed by referring to

half, providing a positive seal.

figure 8-8. Positive locking is assured by the locking

NOTE: Do not use a wrench to couple or uncouple

spring (8) with teeth, which engage ratchet teeth on the

series 145 or 155 quick disconnects unless a modified

union nut (5) when the coupling is fully connected. The

union nut is incorporated. Modified union nuts may be

lock spring automatically disengages when the union

identified by the letter C preceding the part number on

nut is unscrewed. An O-ring packing (3) seals against

the nut. On these modified union nuts, a wrench may be

leakage as the coupling halves are joined. Positive

used to assist in tightening the coupling. Torque values

opening of the valves occurs as the halves are

for the various size couplings may be found in the

connected.

aircraft MIM, and should be strictly complied with in

When the coupling halves are joined, the

all instances.

protruding nose (6) of the S4 half contacts the sleeve (4)

Figure 8-9.--Quick disconnects properly and improperly connected.

8-21