1. An article should never be thrown into the bath.

corresponding to various colors are given in table 6-1;

By permitting it to lie on the bottom of the bath, it is apt

however, the accuracy with which temperatures may be

to cool faster on the top side than on the bottom side,

judged by colors depends on the experience of the

thus causing it to warp or crack.

worker and on the light in which the work is being done.

2. The article should be slightly agitated in the

QUENCHING PROCEDURE.--A number of

bath to destroy the coating of vapor, which might

liquids may be used for quenching steel. Both the

prevent it from cooling rapidly.

media and the form of the bath depend largely on the

nature of the work to be cooled. It is important that a

3. An article should be quenched in such a

sufficient quantity of the media be provided to allow the

manner that all parts will be cooled uniformly and with

metal to be quenched without causing an appreciable

the least possible distortion.

change in the temperature of the bath. This is

4. Irregularly shaped sections should be

particularly important where many articles are to be

immersed in such a manner that the area with the

quenched in succession.

biggest section enters the bath first.

The tendency of steel to warp and crack during the

Quenching Media.--In certain cases water is used

quenching process is difficult to overcome because

in the quenching of steel during the hardening process.

certain parts of the article cool more rapidly than

The water bath temperature is normally held at 18C

others. Whenever the transformation of temperature is

(65F). For specific applications, other bath

not uniform, internal strains are set up in the metal that

result in warping or cracking, depending on the severity

temperatures may be used; however, cold water may

of the strains. Irregularly shaped parts are particularly

warp or crack the part, and hot water may not produce

susceptible to these conditions, although parts of an

the required hardness.

even section are often affected in a similar manner.

A 10-percent salt brine solution is used when

Operations such as forging and machining may set up

higher cooling rates are desired. A 10-percent salt brine

internal strains in steel parts; therefore, it is advisable to

solution is made by dissolving .89 pounds of salt per

normalize articles before attempting the hardening

gallon of water.

process. The following recommendations will greatly

reduce the warping tendency and should be carefully

Oil is much slower in action than water, and the

observed:

tendency of heated steel to warp or crack when

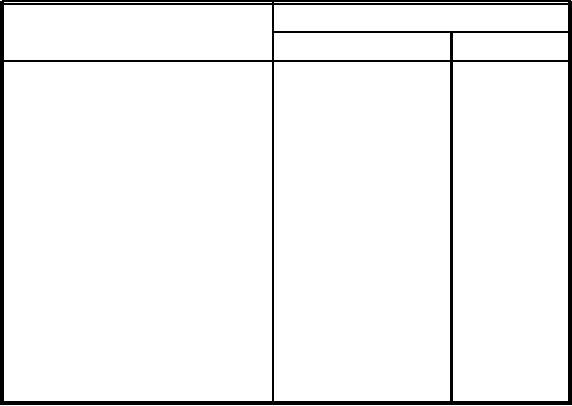

Table 6-1.--Color Chart for Steel at Various Temperatures

COLOR

METAL TEMPERATURE

Degrees C

Degrees F

Faint red

482

900

Blood red

566

1,050

Dark cherry

579.5

1,075

Medium cherry

677

1,250

Cherry or full red

746

1,375

Bright red

843

1,550

Salmon

899

1,650

Orange

940.5

1,725

Lemon

996

1,825

Light lemon

1,079.5

1,975

White

1,204

2,200

Dazzling white

1,288

2,350

6-40