As in the case of hardening, tempering tempera-

quenched may be greatly reduced by its use.

tures may be approximately determined by color. These

Unfortunately, parts made from high-carbon steel will

colors appear only on the surface and are due to a thin

not develop maximum hardness when quenched in oil

film of oxide, which forms on the metal after the

unless they are quite thin in cross section. In aircraft

temperature reaches 220C (428F). To see the

parts, however, it is generally used, and is

recommended in all cases where it will produce the

tempering colors, you must brighten the surface. When

desired degree of hardness.

tempering by the color method, an open flame or heated

iron plate is ordinarily used as the heating medium.

For many articles, a bath of water covered by a film

Although the color method is convenient, it should not

of oil is occasionally used. When the steel is plunged

be used unless adequate facilities for determining

through this oil film, a thin coating will adhere to it.

temperatures are not obtainable. The temperatures and

This action retards the cooling of the water slightly,

corresponding oxide colors are given in table 6-2.

thus reducing the tendency to crack due to contraction.

ANNEALING AND NORMALIZING.--When

Straightening of Parts Warped in Quenching.--

steel is heated to a point above its critical range, a

Warped parts must be straightened by first heating to

condition referred to as "austenite" is produced. If

below the tempering temperature of the article, and

slowly cooled from above its critical temperature, the

then applying pressure. This pressure should be

austenite is broken down and a succession of other

continued until the piece is cooled. It is desirable to

conditions are produced, each being normal for a

retemper the part after straightening at the straightening

particular range of temperatures. Starting with

temperature. No attempt should be made to straighten

austenite, these successive conditions are martensite,

hardened steel without heating, regardless of the

troostite, sorbite, and finally pearlite.

number of times it has been previously heated. Steel in

its hardened condition cannot be bent or sprung cold

The most important step in annealing is to raise the

with any degree of safety.

temperature of the metal to the critical point, as any

hardness that may have existed will then be completely

TEMPERING.--Steel that has been hardened by

removed. Strains that may have been set up through

rapid cooling from a point slightly above its critical

heat treatment will be eliminated when the steel is

range is often harder than necessary, and generally too

heated to the critical point, and then restored to its

brittle for most purposes. In addition, it is under severe

lowest hardness by slow cooling. In annealing, the steel

internal strain. To relieve the strains and reduce

must never be heated more than approximately 28 to

brittleness, the metal is usually tempered. This is

40C (50 to 75F) above the critical point. When large

accomplished in the same types of furnaces that are

articles are annealed, sufficient time must be allowed

used for hardening and annealing.

for the heat to penetrate the metal.

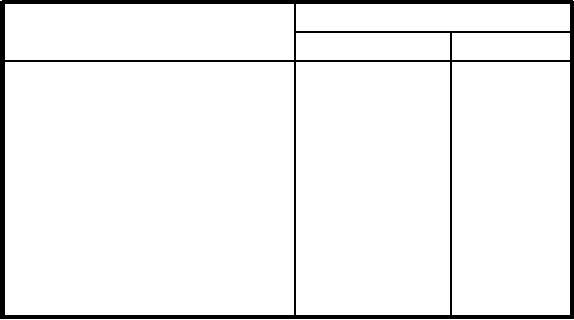

Table 6-2.--Color Chart for Various Tempering Temperatures of Carbon Steel

OXIDE COLOR

METAL TEMPERATURE

Degrees C

Degrees F

Pale yellow

220

428

Straw

230

446

Golden yellow

243

469

Brown

254

491

Brown dappled with purple

266

509

Purple

277

531

Dark blue

288

550

Bright blue

297

567

Pale blue

321

610

6-41