catapult breech V-grooves when the seat is installed in

and bottom seat bucket slippers. The slippers provide

the aircraft.

smooth movement of the seat bucket and have threaded

studs to attach the seat bucket to the main beam.

Bottom Cross-Beam

Friction pads in the studs restrict lateral movement of

the seat bucket. Drogue bridle retaining channels are

The bottom cross-beam is machined from solid

secured to the rear of both main beams. Locating pins

light alloy and retains the main beams at the bottom

for the parachute container hooked brackets are bolted

end. Incorporated into the cross-beam is a gas passage

to the upper outside face of each main beam.

that forms part of the drogue bridle release system.

Interference blocks on the RH beam (forward seat) or

LH beam (aft seat) correspond with interference

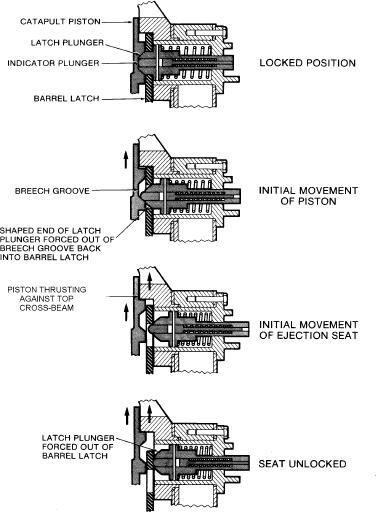

Top Latch Assembly

devices on the catapult and the seat bucket to ensure

that only the correct assemblies are installed in forward

The top latch assembly fitted to the LH main beam

and aft cockpits (fig. 2-5).

secures the seat structure to the catapult. The assembly

consists of a housing with a spring-loaded latch

Top Cross-Beam

plunger, one end of which is shaped to engage the

catapult piston. The plunger may be withdrawn using

The top cross-beam receives and positions the top

the top latch withdrawal tool (handwheel). Passing

of the catapult and takes the full thrust of the catapult

through the center of the latch plunger is a

during ejection. Incorporated into the cross-beam is the

spring-loaded indicator plunger. When the ejection seat

upper drogue bridle release unit, which attaches the

is fitted to the catapult and the handwheel is removed,

upper leg of the drogue bridle to the seat. The studs

the latch plunger passes through the top cross-beam and

securing the RH main beam to the top cross-beam also

engages with the barrel latch. The shaped end of the

retain the RH parachute container mounting bracket.

plunger protrudes still further to engage the groove of

Two of the studs securing the LH main beam to the top

the catapult piston. Operation of the top latch is shown

cross-beam also retain the top latch assembly. A dowel

in figure 2-7.

in the top cross-beam is positioned in one of the

Figure 2-7.--Operation of the top latch assembly.

2-7