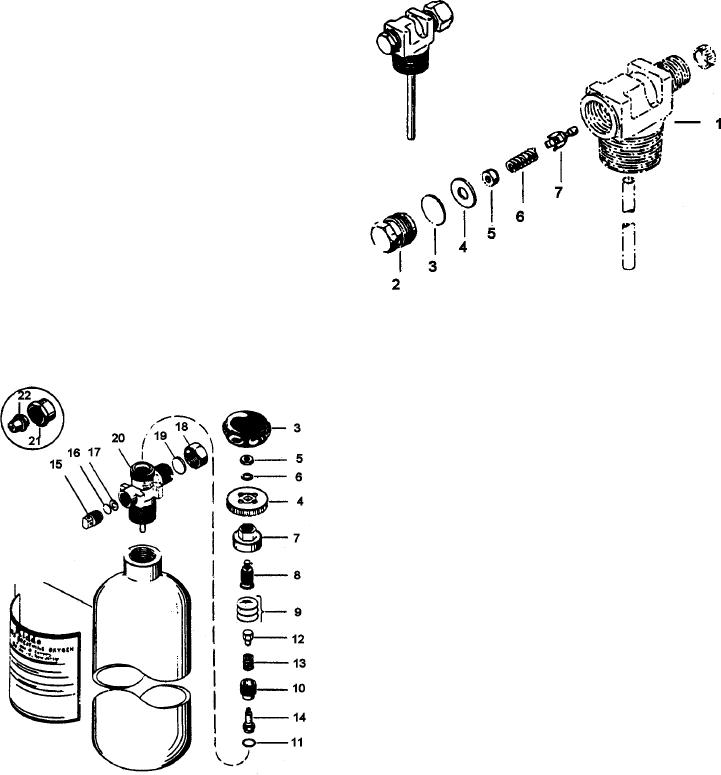

valve (figs. 7-1 and 7-2). Opening the handwheel

operated valve assembly releases the contents of the

cylinder. The handwheel has four 5/15-inch diameter

holes for the attachment of remote operation

equipment, if needed.

The valve is equipped with a fusible metal safety

plug and a safety disc to release the contents of the

cylinder if the pressure becomes excessive because of

high temperature. The safety plug is filled with a fusible

metal designed to melt at temperatures ranging from

208F to 220F (97.8C to 104.5C).

The cylinder and valve assembly is connected to

the oxygen tubing by soldering the tubing to a coupling

nose and securing the nose to the valve outlet with a

coupling nut.

4. DISC WASHER

1. SELF-OPENING

The self-opening (automatic) oxygen cylinder

5. SPRING NEST

HIGH-PRESSURE OXYGEN

6. SPRING

VALVE ASSEMBLY

valve is automatically opened when it is connected to

7. ASSEMBLY CHECK

2. SAFETY PLUG ASSEMBLY

the oxygen line. The use of this type of valve permits

3. SAFETY DISC

Figure 7-2.--Self-opening oxygen cylinder valve.

remote location of the oxygen cylinder to places less

vulnerable during combat and more readily accessible

for servicing.

Regulators

The success or failure of high-altitude flight

depends primarily on the proper functioning of the

oxygen breathing regulator. Acting as a metering

device, the regulator is the heart of the oxygen system.

To perform successfully in an aircraft system, a

regulator must deliver the life-supporting oxygen in the

quantities demanded throughout its entire range of

operation.

Although personnel of the Aircrew Survival

Equipmentman (PR) rating are primarily responsible

for maintenance of regulators, the AME is responsible

for performing operational checks in the aircraft and for

10. BUSHING

1. CYLINDER

removal and installation. In other words, the AME

11. GASKET, BUSHING

2. LABELINSTRUCTION

12. CAP, SPINDLE

ON WALTER KIDDE

removes a malfunctioning regulator from the aircraft

13. SPRING

CYLINDERS

and delivers it to the shop where the PR determines the

14. SEAT, VALVE

3. HANDGRIPS

trouble and makes the necessary repairs. When the

15. PLUG, SAFETY

4. HANDWHEEL

trouble is corrected, the AME reinstalls the regulator in

16. DISC, SAFETY

5. NUT, HANDWHEEL

the aircraft.

17. WASHER, SAFETY DISC

6. WASHER, LOCK

18. CAP, OUTLET

EXTENSION TEETH,

19. WASHER, OUTLET CAP

BRONZE, NO. 10

Tubing

20. BODY, VALVE

7. CAPS, VALVE

21. NUT, COUPLING

8. STEM, UPPER

Two types of tubing are used in aircraft oxygen

22. NOSE, COUPLING

9. DIAPHRAGM (SET OF 3)

systems. Low-pressure aluminum alloy tubing is used

Figure 7-1.--Gaseous oxygen cylinder and handwheel valve

in lines carrying pressures up to 450 psi. High-pressure

assembly.

7-5