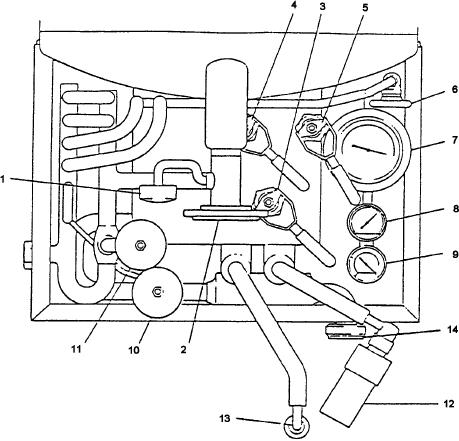

8. TRANSFER TANK PRESSURE GAUGE (P-2)

1. STORAGE TANK PRESSURE GAUGE (P-1)

9. CONVERTER FULL INDICATOR GAUGE (F1)

2. STORAGE TANK LIQUID LEVEL GAUGE (LG-1)

10. FILL-DRAIN LINE SHUTOFF VALVE (LV-1)

3. CONVERTER VENT LINE SHUTOFF VALVE (GV-4)

11. STORAGE TANK VENT LINE SHUTOFF VALVE (GV-6)

4. TRANSFER TANK VENT LINE SHUTOFF VALVE (GV-3)

12. FILLER VALVE (C-2)

5. TRANSFER TANK FILL LINE SHUTOFF VALVE (LV-2)

13. CONVERTER VENT LINE CONNECTION (C-3)

6. TRANSFER TANK PRESSURE BUILDUP VALVE (GV-5)

14. FILL-DRAIN LINE COUPLING (C-1)

7. TRANSFER TANK LIQUID LEVEL GAUGE (LG-2)

Figure 8-2.--Liquid oxygen servicing trailer controls and indicators.

TRANSFER TANK PRESSURE GAUGE.--

TRANSFER TANK FILL LINE SHUTOFF

(Fig. 8-2, item 8). The pressure gauge indicates the

VALVE.--(Fig. 8-2, item 5). The valve is used to

pressure in the transfer tank. The pressure in the

control the gravity flow of liquid oxygen from the

transfer tank must be greater than the pressure in the

storage tank to the transfer tank.

storage tank to achieve transfer of liquid since the

TRANSFER TANK PRESSURE BUILDUP

converter is vented into the storage tank during

VALVE.--(Fig. 8-2, item 6). The pressure buildup

converter fill operation. The gauge is calibrated to read

valve controls the flow of liquid oxygen from the

0 to 160 psig. Safe operating pressure is 0 to 90 psig and

bottom of the transfer tank to the pressure buildup

is indicated by a green band; a red band indicates unsafe

(PBU) coil. The PBU coil is a heat exchanger where the

pressure of 90 to 160 psig.

liquid oxygen is exposed to ambient temperature and is

converted to gas. As the liquid changes to gas it

CONVERTER FULL INDICATOR GAUGE.--

expands. The output gas of the PBU coil is fed back to

(Fig. 8-2, item 9). The full indicator gauge (marked

the transfer tank vapor space, providing pressure to

LIQUID-GAS) is a vapor pressure thermometer

discharge liquid to the converter. This valve is open

that monitors the converter vent line temperature.

only when pressure is required to fill the converter.

During transfer of liquid to a converter, the gauge

indicates GAS temperature in the converter fill

TRANSFER TANK LIQUID LEVEL GAUGE.--

line. When the converter is full, the vent line is

(Fig. 8-2, item 7). The liquid level gauge indicates the

filled with liquid oxygen overflow. The converter

level of liquid oxygen in the transfer tank. The gauge is

vent line temperature drops and the gauge indicator

magnetically and mechanically coupled to a float

moves to the LIQUID position and indicates a full

sensor inside the transfer tank. The gauge is calibrated

converter.

in percent of full.

8-3