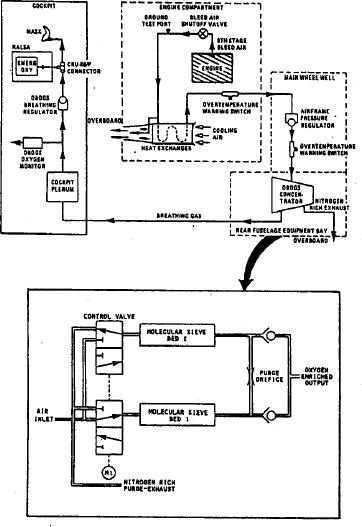

SYSTEM OPERATION

The OBOGS, shown in figure 7-21, receives engine

bleed air from the outlet of the air-conditioning heat

exchanger. The partially cooled air passes through an

air temperature sensor to a pressure reducer assembly.

The air is then routed to the concentrator. The

concentrator has a rotary valve that alternates the

airflow over the molecular sieve beds. The sieve beds

absorb the nitrogen and allow the oxygen and argon to

pass through. Two molecular sieve beds are used in the

concentrator so that while one is absorbing, the other is

desorbing (releasing) nitrogen. This method allows a

continuous flow of oxygen to the system. After the

concentrator, the oxygen flows to a plenum assembly

that acts as a surge tank and an accumulator. The

plenum also functions as a heat exchanger to heat or

cool the oxygen to approximately cockpit temperature.

Before the oxygen reaches the oxygen regulator, the

oxygen performance monitor senses the partial

pressure of the gas, and provides a signal to the pilot

whenever the pressure exceeds prescribed limits. The

oxygen then flows through the regulator to the pilot's

mask.

Q7-23.

An OBOGS system availability may be as

high as what percent?

Q7-24.

True or False. An OBOGS system has a

Figure 7-21.--Onboard oxygen generating system (OBOGS)

schematic.

reduced chance for potential accident.

Q7-25.

What are the three basic components of an

Q7-27.

During OBOGS operation, when one sieve

OBOGS system?

bed is absorbing, what is the other sieve bed

Q7-26.

What component has a built-in test?

releasing?

7-22