Diluter control lever in 100% OXYGEN

gaseous oxygen and then delivers it to the crew. The

oxygen source of this system is a supply of LOX stored

position

in a 10-lilter converter. System pressure is maintained

Supply valve control lever in OFF position

at 75 to 110 psi by a pressure control valve and a

Regulator and surrounding area free of dirt and

pressure relief valve.

hydrocarbons

Through a process of controlled evaporation within

Delivery hose and connector for cuts, fraying,

the converter assembly, LOX is converted to gaseous

oxygen as required by the occupant of the aircraft. The

kinking, hydrocarbons, and general condition

oxygen is delivered to the pilot after being warmed to a

If discrepancies are found or suspected, mainte-

safe breathing temperature in the heat exchanger. The

nance control should be notified. Regulators that do not

flow of oxygen is controlled in the cockpit by the

pass inspection and cannot be repaired in the aircraft

shutoff valve.

are removed and replaced by ready-for-issue (RFI)

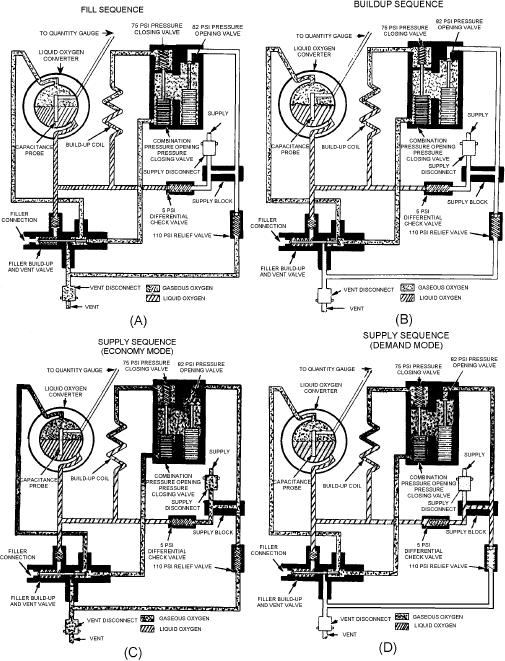

The units that make up the converter assembly

regulators. Non-RFI regulators are forwarded to the

control the major part of the operation of the LOX

nearest maintenance activity having repair capability.

system automatically. The LOX converter has three

sequences of operation--fill, buildup, and supply (fig.

SYSTEM OPERATION

7-17). In the supply sequence, the converter alternates

The LOX system shown in figure 7-7 is an example

between the economy and demand modes of operation.

of a typical system. This system converts LOX to

Figure 7-17.--Liquid oxygen converter operation.

7-18