and repair of LOX lines. All low-pressure tubing used

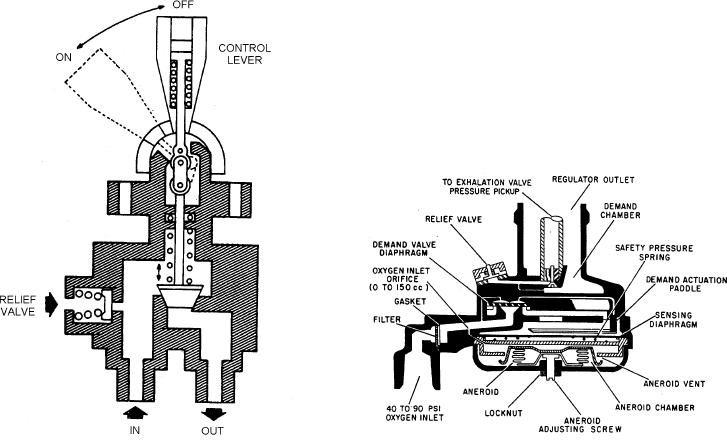

Oxygen Shutoff Valve

in LOX systems is aluminum alloy 5052 tubing and is

The oxygen shutoff valve is installed in the system

non-heat treatable. It is manufactured in seamless,

to control the flow of oxygen to the pilot or flight crew,

round lengths, and is annealed to provide greater

as required. Figure 7-12 illustrates a typical manually

flexibility. Aircraft oxygen systems are fitted with

operated two-position valve. This valve has an inlet

5/16-, 3/8-, and 1/2-inch sizes. Low-pressure tubing

port, outlet port, and a relief port. The pressure-relief

also is installed from the pressure reducer outlets in

valve is located in the inlet chamber to protect the

reduced high-pressure oxygen systems.

oxygen regulator and crewmember from excessive

Oxygen Regulators

system pressure if there is a malfunction of the liquid

oxygen converter. Also, this valve relieves excessive

Regulators used with LOX systems are either

pressure due to thermal expansion of gaseous oxygen

console-mounted or miniature mask-mounted. The

trapped within the system when not in use. If the

miniature mask-mounted regulator was especially

oxygen system incorporates a console-mounted

designed for use with aircraft that have ejection seats.

regulator, the shutoff valve is part of the regulator.

The console-mounted regulator is normally used in

large non-ejection seat-equipped multi-place aircraft

Composite Quick-Disconnect Coupling

such as the E-6B and P-3.

The purpose of the composite quick-disconnect

MINIATURE OXYGEN BREATHING REG-

coupling is to provide a single-point connection for

ULATOR.--The miniature mask oxygen regulator,

quickly connecting and disconnecting the pilot with

shown in a cutaway view in figure 7-13, is intended

aircraft oxygen, anti-g, communications, and ventila-

primarily for use in aircraft having a low-pressure LOX

tion air services.

system and ejection seats. It is often referred to as a

miniature mask-mounted regulator. Since it weights

Oxygen Lines

only 2.3 ounces and measures approximately 2

5/8-inches in length and width, it is easily mounted on

LOX systems are classed as low-pressure systems.

the oxygen mask or user's torso harness. It is designed

As such, low-pressure tubing is used in manufacture

so that with an inlet pressure of 40 to 120 psi, it will

deliver 100-percent oxygen automatically to the user

between the altitudes of 0 and 50,000 feet.

Oxygen at system pressure, warmed to a

comfortable temperature, flows into the regulator inlet

port to the demand valve diaphragm. A small passage

from the inlet line sends this pressure to the backside of

the diaphragm; thus, the demand valve diaphragm is

Figure 7-12.--Oxygen shutoff valve.

Figure 7-13.--Cutaway view of a miniature oxygen regulator.

7-14