with the tube in the outlet port of the unit, so that only

pressure balanced except for the light imbalance caused

the pressure sent to it by the exhalation valve pickup

by an area advantage on the backside of the diaphragm,

tube compensates the exhalation valve.

which provides a positive sealing force.

The vacuum caused by inhalation causes the

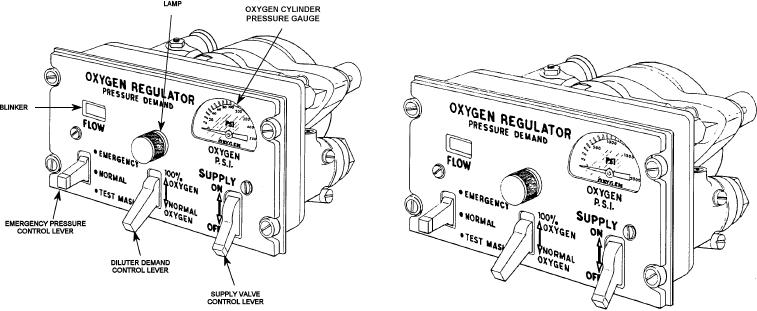

AIRCRAFT-MOUNTED OXYGEN REGULA-

sensing diaphragm to tilt downward, pushing down the

TORS.--The MD series regulator is being used in

demand-actuating paddle. As the paddle is forced

several multi-place naval aircraft. There are two types

downward, its base is lifted from a seat, which seals a

of regulators in this series--the MD-1 (low-pressure)

second passageway from the backside of the demand

(fig. 7-14) and the MD-2 (high-pressure) (fig. 7-15).

valve diaphragm. Raising the paddle base allows flow

The only difference found in these regulators is operat-

from this area, which causes a pressure drop behind the

ing pressure. The operating pressure of the MD-1 regula-

demand valve diaphragm and allows inlet pressure to

tor is 50 to 500 psi. The pressure gauge reads 0 to 500

lift the diaphragm from its seat, and oxygen flow occurs.

psi. The operating pressure of the MD-2 regulator is 50

to 2,000 psi. The pressure gauge reads 0 to 2,000 psi.

Safety pressure is obtained by the safety pressure

spring, which deflects the sensing diaphragm, causing

The following controls and indicators are located

flow through the unit until the force created by mask

on the front panel of the regulator. The small

pressure equals the force of the spring. This returns the

oblong-shaped window area on the left side of the panel

sensing diaphragm to a balanced condition.

marked FLOW indicates the flow of oxygen through

the regulator by a visible blinking action. The pressure

Automatic pressure breathing is obtained by

gauge is on the upper right and indicates inlet pressure

diverting a small volume bleed from the inlet passage to

to the regulator. The regulator has three control levers.

the aneroid chamber. This bleed is normally vented

A supply valve controller lever, on the lower right

from the aneroid cavity past the area labeled aneroid

corner, is used to control the supply of oxygen to the

vent. At the altitude at which pressure breathing is to

regulator; a diluter control lever, on the lower center of

begin, the lip of the aneroid comes in contact with the

the panel, has two positions--100% OXYGEN and

seat, closing off the aneroid vent and building up

NORMAL OXYGEN; an emergency pressure control

pressure, which reacts on the sensing diaphragm. The

lever, on the lower left of the panel, has three

pressure lifts the sensing diaphragm, causing flow until

positions--EMERGENCY, NORMAL, and TEST

the mask pressure exerts a force on the sensing

MASK, and with the diluter lever in the 100%

diaphragm equal to the force exerted by pressure

OXYGEN position, the regulator delivers 100 percent

buildup in the aneroid chamber.

oxygen upon inhalation by the user. In the NORMAL

The relief valve on the unit acts as a pilot device to

OXYGEN position, the regulator delivers a mixture of

open the exhalation valve of the mask. This is done by

air and oxygen with the air content decreasing until a

isolating the pressure pickup of the exhalation valve

cabin altitude of approximately 30,000 feet is reached.

Above this altitude, 100 percent oxygen is delivered to

the user upon inhalation.

Figure 7-14.--Aircraft panel mounted oxygen regulator, type

Figure 7-15.--Aircraft panel mounted oxygen regulator, type

MD-1.

MD-2.

7-15