by this volume of oxygen acting on the demand valve

6. The addition of ambient air to oxygen is

lever assembly to the extent that the positive pressure is

controlled by the manual diluter control lever (13) and

built up at the pressure outlet as the altitude increases.

by the diluter aneroid assembly (14), which

automatically produces a 100-percent oxygen

10. Additional safety is obtained through the

concentration at altitudes above 32,000 feet.

inclusion of the second-stage relief valve assembly (23)

in the regulator.

7. The aneroid check valve assembly (15)

prevents a flow of oxygen out through the inlet ports.

TURNAROUND/PREFLIGHT/POSTFLIGHT/

TRANSFER INSPECTIONS.--These inspections

8. The emergency pressure control lever (16)

are visual inspections performed in conjunction with

applies force to the emergency pressure control test

the inspection requirements for the aircraft in which the

spring (17), which mechanically loads the emergency

regulators are installed. Refer to table 7-2 for assistance

pressure diaphragm through the control lever and

in troubleshooting.

center assembly (18). Mechanical loading of the

emergency pressure diaphragm provides positive

Visually inspect the following:

pressure at the regulator outlet.

Electrical performance of the panel light

9. Both automatic safety pressure and pressure

Legibility of all marking

breathing at altitudes above 30,000 feet are provided

Plastic lighting plate for cracks and dis-

through pneumatic actuation of the aneroid assembly

coloration

(19). This function begins near 27,000 feet altitude. The

Low or improper reading on regulator pressure

force exerted on the diaphragm assembly (20) by the

gauge

aneroid assembly actuates the pressure breather valve

Emergency pressure control lever in NORMAL

assembly (21), and the oxygen flows to the diaphragm

and the plate assembly (22), which is pressure loaded

position

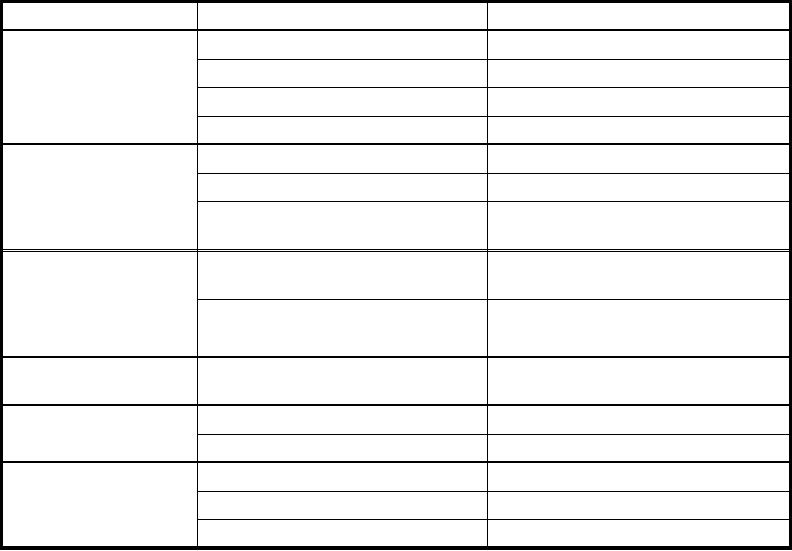

Table 7-2.--Gaseous Oxygen System Troubleshooting

TROUBLE

PROBABLE CAUSE

REMEDY

Oxygen cylinder pressure Defective gauge

Replace regulator

gauge fails to indicate

Blocked or leaking supply line

Replace or clean supply line to regulator

proper pressure

Low cylinder pressure

Refill

Defective manifold inlet assembly

Replace regulator

Oxygen not available at Regulator controls improperly positioned

Correct position of controls

mask with proper pressure

Hose to mask is kinked

Straighten hose and reposition outlet

source to regulator and

other than emergency setting Regulator not functioning properly

Replace regulator

on regulator

Kink or other malfunction between hose Replace or readjust equipment as necessary

Oxygen not available at

and mask

mask with proper pressure

source to regulator and

Faulty linkage from emergency pressure Replace regulator

regulator controls set at

control lever

EMERGENCY

Oxygen available at mask Defective blinker assembly

Replace regulator

but flow is not indicated

Gauge pressure drops when

Loose or leaking connections

Tighten or replace connections as necessary

regulator is not in use

Defective manifold inlet assembly

Replace regulator

Panel light fails to light

Burned out lamp

Replace regulator

Faulty light assembly

Replace lamp

Faulty electrical hookup to power source

Repair electrical hookup

7-17