NAVAIR A 1 - NAO S H - S A F - 0 0 0 / P 5 1 0 0 / 1 ,

LOX converters and servicing trailers should be

stowed or parked so that they are protected from

N AV A I R O S H R e q u i r e m e n t s f o r t h e S h o r e

excessive heat and direct rays of sunlight as much as is

Establishment

practical. All LOX should be segregated from

NAVAIR 06-30-501, Technical Manual of

containers of other gases or liquids and all flammable

Oxygen/Nitrogen Cryogenic Systems

materials. Hydrocarbons such as oil and grease in the

oxygen handling area could result in death, serious

All personnel handling oxygen and maintaining

injury, and property damage.

gaseous or liquid oxygen systems should be thoroughly

familiar with all precautions and procedures listed in

Smoking, open flames, or sparks are not permitted

the latest revisions to these publications. They also

in any oxygen handling area. When transferring

should be familiar with the specific precautions

oxygen, provide adequate ventilation to prevent the

provided in the applicable aircraft MIM and those

formation of an oxygen-enriched atmosphere.

pertaining to the type of equipment being used to

Avoid spilling LOX on floors or deck areas. In case

service such systems.

of accidental spillage, ventilate the area. Intentional

draining of LOX from a system or container must be

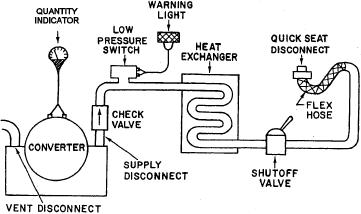

SYSTEM COMPONENTS

caught in a clean drain pan and allowed to evaporate in

a suitable open area that will not present a hazard.

Aircraft LOX systems are similar to gaseous

oxygen systems except that the several cylinders of

In the event that LOX is spilled on clothing,

gaseous oxygen are replaced by one or more LOX

separate clothing from skin contact immediately and

converters. The use of more than one converter

thoroughly air clothing for 1 hour to allow dilution of

provides for an adequate supply of oxygen on

the oxygen concentration. When an uninsulated

long-range flights or where there is more than one

container of LOX is touched or when there is any

crewmember using the oxygen systems. In addition to

reason to suspect some part of the body has been frozen

the converters, most LOX systems contain a heat

or chilled, the area should be thoroughly washed or

exchanger; filler, pressure control, relief, and shutoff

immersed in clean water that is slightly above body

valves; quick-disconnect couplings; low-pressure

temperature (approximately 104F to 113F). The

switch; oxygen lines and regulators; and quantity

exposed area should then be loosely wrapped with a

indicating units. See figure 7-7 for a schematic diagram

clean, dry dressing, and medical aid should be sought

of a LOX system.

immediately.

When servicing and maintaining LOX systems, the

AME will be required to transfer LOX from servicing

trailers to aircraft converters, and occasionally from the

converter to the drain pan. The AME also will be

required to remove and install converters and other

components of LOX systems. All servicing and

maintenance of LOX systems must be done in

accordance with instructions contained in the

applicable aircraft MIM. All safety precautions

concerning the handling of LOX must be adhered to.

When a completely empty system is being

serviced, the LOX should be added slowly to cool the

converter down to the storage temperature (297F).

The converter could otherwise be damaged by thermal

shock or rapid pressure buildup.

Additional gaseous and liquid oxygen safety

precautions and handling procedures are provided in

Figure 7-7.--LOX system schematic.

the following publications:

7-11