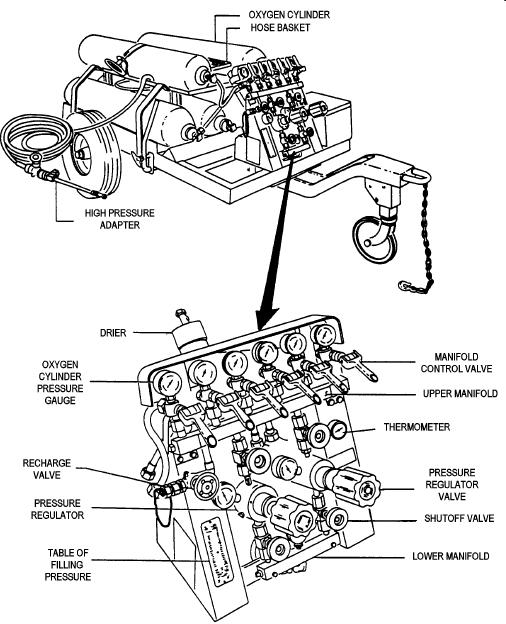

Figure 8-5.--Type No-2 gaseous oxygen servicing trailer.

lower/outlet shutoff valves from the outlet side of the

necessity of removing the cylinders. When not in use,

regulators, a delivery pressure gauge, and a flexible

the valve adapter should be fitted with a dust cap.

hose that connects the lower manifold to the drier

SHUTOFF VALVES.--There are four shutoff

assembly.

valves, one on the inlet side of each pressure regulator

DRIER ASSEMBLY.--The drier assembly is a

and one on the outlet side of each regulator. These

reservoir containing a chemical drying agent through

shutoff valves control the flow of oxygen from the

which oxygen must pass before going through the

upper manifold to the lower manifold, via the regulator.

servicing hose. This chemical drier is provided to

When the shutoff valves on the inlet and outlet

remove any moisture in the oxygen supply. The oxygen

sides of the regulator are open, the pressure regulator is

flows into the bottom of the drier, passes up through the

ready for use. By turning the regulator control handle

drying agent, and out through the servicing hose.

clockwise, the pressure (as read on the gauge attached

to the regulator) will increase. Turning the control

SERVICING HOSE AND LINE VALVE.--The

handle counterclockwise decreases pressure.

servicing hose is a high-pressure, non-linking, metallic

flexible hose. The line-servicing valve is attached to the

LOWER MANIFOLD.--The lower manifold

servicing hose and is used to control the flow of oxygen

provides connections/mountings for the two

to the system being charged.

8-11