Operation

NOTE: NEVER completely expend the supply

of oxygen from a cylinder. Always leave a

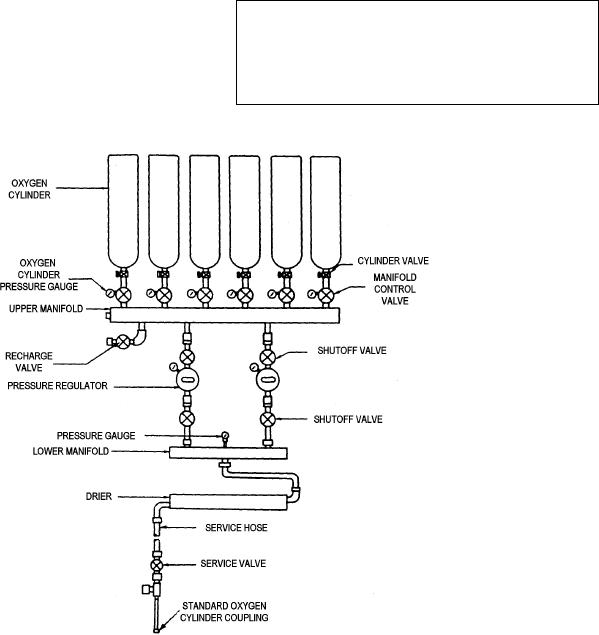

The six supply cylinders are connected by means of

residual pressure in excess of 50 psi.

flexible hoses to their respective control valves (fig.

REMOVAL OF EMPTY CYLINDERS.--When

8-6). The six control valves are attached to the upper

the trailer has been in use and cylinder pressure is low,

manifolds. A pressure gauge is screwed into each

the cylinders are removed as described below.

control valve at a point below the seat. This allows each

cylinder pressure to be easily read.

1. Close all lever valves on the manifold prior to

removing any cylinders.

The oxygen flows from the upper manifold through

either of two pressure regulators via two shutoff valves.

2. Close the cylinder shutoff valves.

The oxygen is collected in the lower manifold

3. Disconnect the flexible hose that connects the

where a gauge registers the pressure of the delivery side

cylinder to the manifold.

of the system. The lower manifold is connected by

4. Loosen the clamping arrangement that holds

flexible hose to a drier that filters and dries the oxygen.

the cylinders to the trailer.

The servicing hose connects directly to the drier and

5. Install the cylinder safety caps.

has a line-servicing valve on the terminal end. The

line-servicing valve is fitted with a standard oxygen

6. Remove the empty cylinders.

cylinder connection.

Loading Cylinders

CAUTION

The servicing trailer is capable of having its

Do not attempt to remove empty cylinders while

cylinders recharged without removal. However, many

charging.

operating activities replace the empty cylinders with

full cylinders.

Figure 8-6.--Type No-2 gaseous oxygen servicing trailer (schematic).

8-12