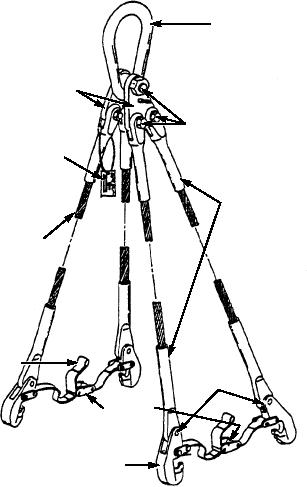

binations of types). These types are wire rope, fabric or

Q13-12. What size is the water tank quick-fill connec-

webbing, structural steel or aluminum, and chain. A

tion on the A/S32P-25?

typical aircraft crash sling is shown in figure 13-7.

1.

1

inch

2.

1 1/2 inch

STORAGE OF LIFTING SLINGS

3.

2

inch

4.

2 1/2 inch

Whenever possible, aircraft slings should be stored

indoors in a clean, dry, well-ventilated area so as to be

protected from moisture, salt atmosphere, and acids.

AIRCRAFT LIFTING SLINGS

Where practical, slings should be hung or secured in a

LEARNING OBJECTIVES: Identify the

storage rig to prevent damage from shifting and

purpose for aircraft lifting slings. Identify the

banging while underway. (Keep in mind that these

components of aircraft lifting slings. Identify

slings must be available for immediate use on deck

procedures for troubleshooting and mainte-

should an emergency arise.) An ideal storage procedure

nance of aircraft lifting slings.

and location must also allow for periodic inspections

Aircraft lifting slings are specialized items of

and availability to reapply proper protective coatings.

support equipment whose function is to facilitate the

INSPECTION OF LIFTING SLINGS

hoisting of aircraft and aircraft components. Slings are

used to hoist aircraft from the pier to carrier decks, clear

The inspection of lifting slings falls into two

crash-damaged aircraft, and remove and install wings

general categories--preinstallation inspections and

and other major components during maintenance

qualification inspections. These inspections are

operations.

discussed in great depth in Inspection and Proofload

Aircraft lifting slings are constructed in accordance

Testing of Lifting Slings and Restraining Devices for

with Military Specification MIL-S-5944 and can be

Aircraft and Related Components, NAVAIR 17-1-114.

classified under four types of construction (or com-

Preinstallation Inspections

HOISTING

Prior to each use, or at least once a month, a com-

RING

plete visual inspection is performed and documented as

follows:

PLATES

Wire rope cables are visually inspected for

knots, fraying, stretching, abrasions, broken wires,

BOLTS

severe corrosion, or other signs of failure. Of particular

TEST / INSP

TAG

importance is the detection of a cable in which a kink

has been pulled through in order to straighten the cable

(commonly called a bird cage) (fig. 13-8). Any

TERMINALS

birdcage on a lifting cable is cause for rejection no

matter where it is located.

WIRE

ROPE

The maximum number of broken wires allowed

in a cable is three per inch, and the broken wires must

be distributed randomly. No two broken wires may be

next to each other. No strand may have more than one

broken wire per pitch length, and no broken wires are

SAFETY

STRAP

permitted within five times the cable diameter of an end

PINS

fitting.

BUCKLES

Fabric straps should be visually inspected for

cuts, holes, severe abrasions, mildew, dry rot, broken

stitches, and frays. They should also be inspected for

SLING HOOK

deterioration due to contact with foreign materials,

ASf13007

such as oils, greases, fuels, and caustic cleaners.

Figure 13-7.--A typical aircraft hoisting sling.

13-14