The most common forklift is the 6,000-pound

COUNTERWEIGHT

model, often called a "6K." For shipboard use, this

All forklifts have some kind of counterweight that

forklift will have a diesel engine, an automatic

transmission, rear steering, and a differential that

Some counterweights are built in as part of the frame,

operates on the same principle as any rear-steering

but most 6K forklifts have removable counterweights to

vehicle (even though this is a front-wheel drive unit).

permit access to components located behind the

Some models are driven by a bull gear system, which is

counterweights. Counterweights are very heavy,

much like a planetary gear system. That is, one small

ranging from about 4,000 pounds and up. Prior to

gear is the drive gear, and it rotates the large outer gear,

removing a counterweight, be sure to check your

which provides the torque required to transport the

technical manual to see if blocks are required to prevent

the forklift from tilting forward when the

The brakes are hydraulic and may or may not be

counterweight is removed.

powered, depending upon the model. Some models

have four-wheel brakes, but many have brakes only on

the two drive wheels. The parking brakes are controlled

by a hand lever. One other type of brake that you will

The hydraulic cylinders for the tilt and carriage

encounter on a forklift is the deadman brake (switch).

assemblies on forklifts are the double-acting type. In

There is a mechanical lever under the seat that releases

this type, fluid must be applied to either side of the

the brakes when you sit down in the drivers seat. When

piston to provide movement in the corresponding

you rise (or fall) off the seat, the spring and lever under

direction. The lift cylinder, however, is single-acting,

the seat activate the brakes to stop the forklift.

which operates similar to the cylinder assemblies of

hydraulic jacks and work stands. Fluid under pressure

is required to raise the piston in the cylinder. When this

pressure is released through a control valve, the weight

WARNING

of the fork, loaded or not, will lower the piston in the

The turning radius of a forklift is very short.

cylinder.

To achieve this short turning radius, the wheel

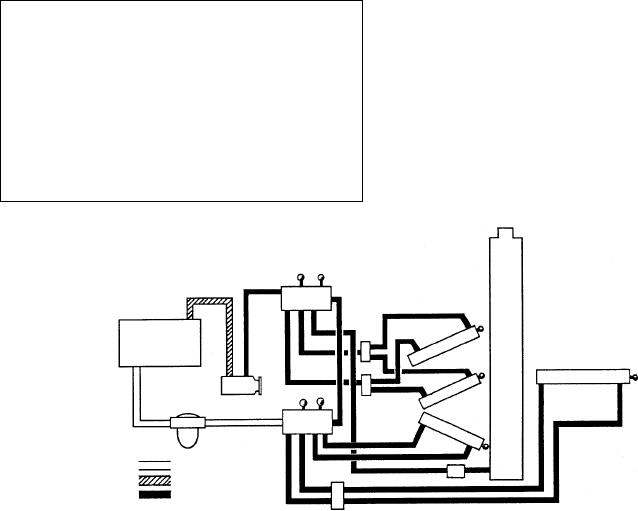

Figure 13-11 shows a schematic for a typical

base is short and the wheels are placed close

forklift hydraulic system. (This schematic is included

together. This gives the forklift its maneuver-

to support the explanation and does not depict any

ability, but it also makes it unstable. Always use

particular model. However, many of the features

caution and common sense when you operate a

included in this system are found in all forklift

forklift.

hydraulic systems.)

3

1

6

5

8

9

5

2

6

4

7

12

RETURN LINES

10

SUPPLY LINE

11

PRESSURE AND

WORKING LINES

ASf13011

1. Reservoir

5. Manifolds

9. Telescopic boom cylinder

2. Pump

6. Tilt cylinders

10. Orifice check valve (restrictor)

3. Control valve (lift and tilt)

7. Shift cylinder

11. Quick disconnects

4. Control valve (shift and telescopic boom)

8. Lift cylinder

12. Filter

Figure 13-11.--Schematic of a typical forklift hydraulic system.

13-17