packed with a powder-type insulating material. The

(called vacuum-jacketed), with point-contact space

space is evacuated to a high degree to minimize heat

rings to prevent the inner liquid-bearing line from

transfer and to hold evaporation losses to a minimum.

touching the outer jacket wall. To keep the heat influx

as low as possible, low thermal conductivity materials

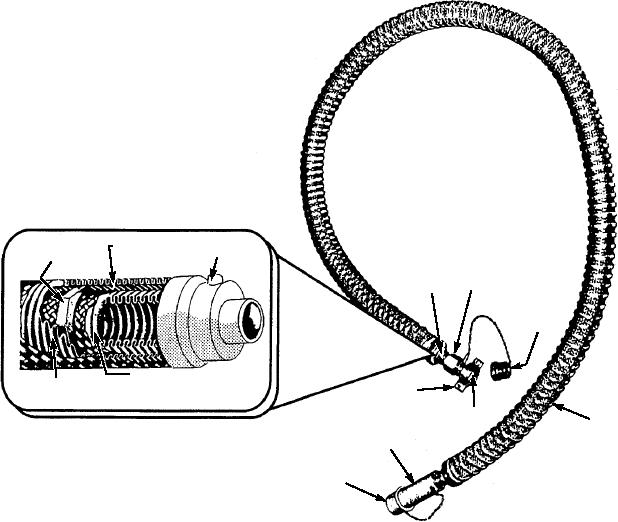

Transfer Lines

are used for insulation, and the spacer design provides

for as small an area of contact between the inner and

Other than large, fixed-facility piping, most liquid

outer walls as possible.

oxygen systems consists of segmented flexible transfer

Flexible hose is more vulnerable to damage than its

lines. The lines are segmented for ease of demounting,

rigid counterpart. To strengthen flexible hoses, they

so that one transfer system can service different types

are built with braided metallic coverings or tough

of equipment. The most common type of line used in

plastic sheaths over the external corrugations.

the field is corrugated, flexible, metal hose (fig. 10-3),

Although such protection provides a degree of

which is constructed of bronze, stainless steel, or

reinforcement, it cannot entirely overcome the effects

aluminum. The bayonet coupling shown in figure 10-3

o f r o u g h h a n d l i n g . H o s e s a r e t o u g h , bu t n o t

is used to connect the service line to an aircraft LOX

indestructible.

converter.

Over pressurization of oxygen hoses is another

On a typical day lines are cooled and warmed many

condition to be avoided. Over pressurization may

times as LOX is drawn from the tanks. The waste of

produce a bellows-like effect if the covering is not

LOX due to cool down losses can be significant. For

securely fastened at the end connections. This may

this reason, transfer lines, like storage tanks, are as

cause separation of the outer cover at the hose collar,

well insulated as possible. Hoses are double-walled

PUMP-OUT

POINT-CONTACT

EVACUATED CONNECTION

SPACE RING

ANNULUS

6

5

3

BRAND-REINFORCED

BRAID-REINFORCED

INNER HOSE

7

OUTER HOSE

8

2

1

1.

FILLER VALVE AND CAP

2.

LIQUID HOSE AND END FITTINGS

4

3.

DUST PLUG AND CHAIN

4.

DUST CAP AND CHAIN

5.

TRANSFER HOSE AND ADAPTER

6.

CONNECTOR AND FILTER

7.

COUPLING WING NUT

8.

CONNECTOR

ASf10003

Figure 10-3.--Corrugated flexible metal hose.

10-3