NOTE: Before starting this procedure, be sure to

CAUTION

don all of the appropriate safety clothing.

Monitor storage tank pressure gauge P-1 closely

1. Ensure that all control valves are closed, except

during cool down. Do not allow pressure in the

for the storage tank vent valve (GV-6).

storage tank to rise above 50 psi.

LV-1: The fill-drain line shutoff valve

LV-2: The transfer tank fill line shutoff valve

8. Monitor the storage tank liquid level gauge

GV-3: The transfer tank vent line shutoff valve

(LG-1) during filling. When the gauge reads 50 gallons,

or LOX starts to flow out of the vent manifold, close the

GV-4: The converter vent line shutoff valve

service valve on the supply tank.

GV-5: The transfer tank pressure buildup valve

9. Close the fill-drain line shutoff valve (LV-1).

2. Ensure that the trailer is level, the caster is down

10. Open the supply tank transfer hose vent valve,

and locked, and that the parking brake is set.

and disconnect the supply tank transfer hose from the

3. Place a clean, oil-free drip pan under the vent

servicing trailer.

valve.

11. Immediately drain the LOX that remains in the

4. Remove the dust covers from the supply tank's

supply tank transfer hose, and loosely replace the

transfer line, and purge the hose. (Purging the hose

coupling cap. Tighten the cap only after all LOX has

vaporized and bled off.

means to allow liquid LOX to flow through the hose,

cooling it until only liquid passes through, and no

vapor.)

WARNING

5. Connect the purged transfer hose to the fill-drain

Use extreme caution when disconnecting the

line coupling (C-1) on the servicing trailer.

transfer hose. Even though the hose has been

drained and the pressure relieved, some LOX

6. Open the servicing trailer's storage tank

will still remain. Do not direct the hose toward

fill-drain line shutoff valve (LV-1).

personnel or other equipment.

7. Slowly open the service valve on the supply

tank, allowing only a partial flow of LOX through the

12. Ensure that all control valves on the servicing

transfer hose and into the trailer. (Considerable

trailer are closed, except for the storage tank vent line

vaporization will take place until the transfer hose,

shutoff valve (GV-6).

fill-drain line, and storage tank of the servicing trailer

have cooled down.)

Filling of the storage tank is now completed.

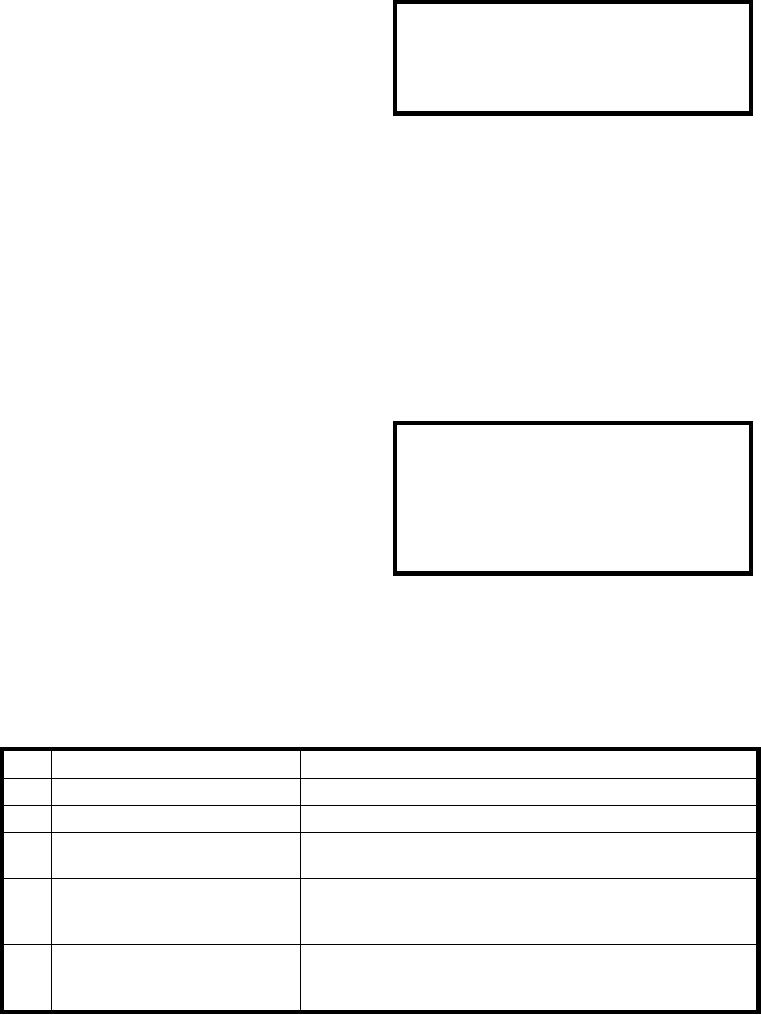

Table 10-1.--LOX Servicing Trailer Controls and Indicators

Code

Component Name

Description of Function

C-1

Fill-Drain Line Coupling

Filling and draining point for the storage tank.

LF-1 Fill-Drain Line Filter

Prevents particles from flowing into the storage tank during filling.

LV-1 Fill-Drain Line Shutoff Valve

Controls the flow of LOX into the storage tank during filling. Also

used to drain the storage tank.

RV-3 Fill-Drain Line Relief Valve

Prevents excessive pressure buildup if the fill-drain line shutoff

valve and service valve of the central supply tank are closed with

cold gas or liquid trapped within the supply line.

GV-6 Storage Tank Vent Line Shutoff

Opened during filling and normal storage where overboard

Valve

discharge is available and safe. Normally closed during short

ground transportation.

10-7