superheated according to the thermal expansion valve

rate of expansion of the refrigerant. The rate of

setting.

expansion of the liquid spray is dependent upon the rate

of heat absorption from the air passing over the

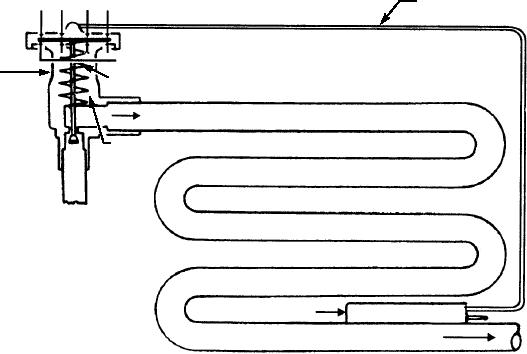

The temperature of the vapor in the middle of the

evaporator tubes. As the refrigerant spray changes to a

coil is 40F. By the time it reaches point C, it is 50F. It

vapor, it absorbs heat from the evaporator. The heat

has absorbed an additional 10F of superheat. The

absorbed by the vapor is called superheat. By the time

thermobulb is mounted on the evaporator at the outlet to

the refrigerant leaves the evaporator, all of it should be

the compressor. The temperature within the bulb is the

in superheated vapor form.

same as that of the evaporator at point C. The pressure

within the thermal bulb, and consequently on the

The metering valve is opened or closed by the

diaphragm within the thermal expansion valve, is 46.7

action of the diaphragm at the top of the thermostatic

psi (P1). This pressure tends to push the diaphragm

valve. A thermobulb is attached to the diaphragm

housing by a small tube. The bulb is filled with the same

down, opening the valve from the receiver. Opposing

type of refrigerant used in the system. Heat felt by the

this force is the 37 psi (P2) exerted against the bottom of

thermobulb causes the refrigerant inside it to vaporize,

the diaphragm by the vapor at the inlet of the evaporator

which increases the pressure inside the bulb. The

coil. A spring pressure of 9.7 psi (P3) added to 37 psi

pressure is transmitted through the attaching tube to the

diaphragm. The increased pressure on the diaphragm

If an increase in load occurs, the superheat in the

causes the metering valve to open. Opening the valve

suction vapor increases, which causes the thermal bulb

increases the refrigerant flow into the evaporator.

temperature and pressure to increase; a greater pressure

In figure 11-11, a thermostatic expansion valve is

on the top of the diaphragm is then exerted. This causes

shown with the evaporator for a cooling unit operating

the valve to open further, allowing an increase in the

at 37 psi suction (low-side) pressure. The refrigerant

flow of refrigerant to the evaporator to restore superheat

moving through the evaporator coil absorbs heat from

to the 10-degree setting of the valve.

the air outside the coil. At point B, it has absorbed

If a decrease in load occurs, the superheat

sufficient latent heat for complete vaporization. At this

decreases, and the pressure in the thermal bulb

point, all the liquid has vaporized. Any additional heat

decreases. Evaporator inlet pressure plus spring

absorbed from the air raises the temperature of the

pressure tends to close the valve, which reduces the

vapor; but the pressure remains at 37 psi. This is the

flow of refrigerant sufficiently to maintain the

suction pressure of the compressor. By the time the

superheat at 10F.

vapor reaches the thermal bulb, point C, it has been

P1 = 46.7 PSIG

CAPILLARY

TUBE

THERMOSTATIC

P2 = 37 PSIG

EXPANSION

VALVE

P3 = 9.7 PSIG

A

37 PSIG, 40o F

PRESSURE

PORT

INLET

37 PSIG, 40o F

FROM

RECEIVER

B

46.7 PSIG, 50 o F

ASf11011

37 PSIG, 50o F

C

OUTLET TO

COMPRESSOR

Figure 11-11.--Thermostatic expansion valve and evaporator.

11-13