Service Valves

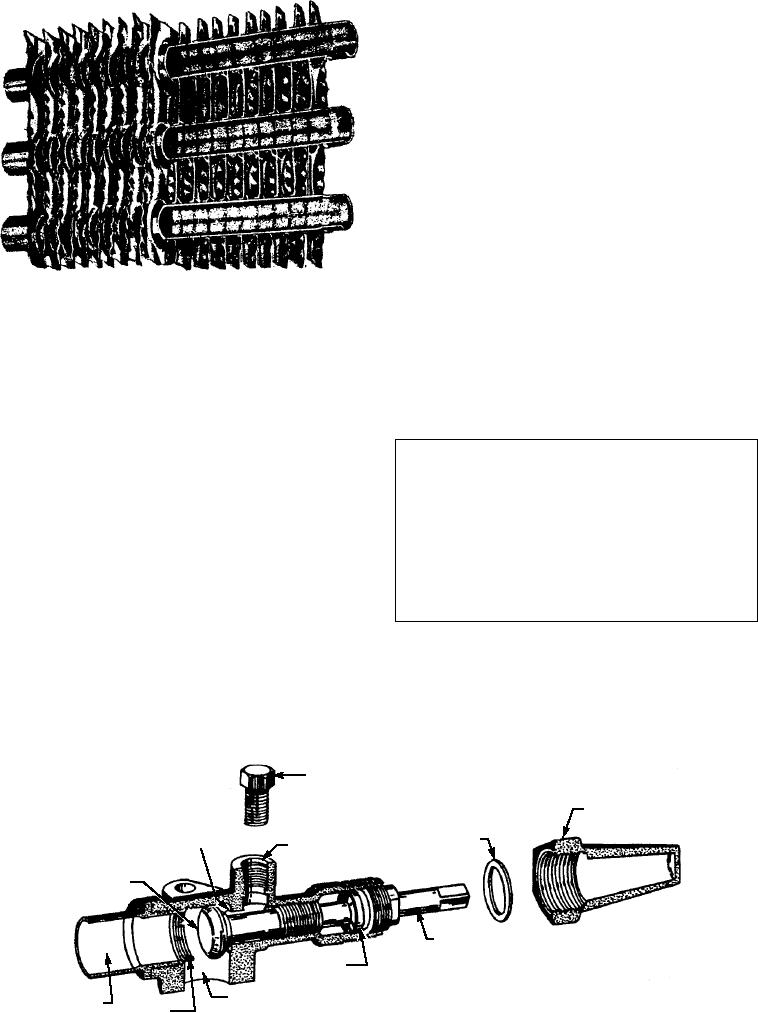

Service valves (fig. 11-13), referred to as discharge

(head) and suction valves, are provided for charging

(filling) the system and for use during some

maintenance operations. The discharge valve is

mounted on the high-pressure port of the compressor;

the suction valve is mounted on the low-pressure side.

Construction of the valves and their method of

operation are identical. However, they differ in size,

use, and placement.

The service valves for the compressor and receiver

have caps that must be removed prior to seating the

valve. There are three "seating" positions: front-seated,

back-seated, and mid-seated.

ASf11012

F R O N T- S E AT E D . -- W h e n t h e v a l v e i s

Figure 11-12.--Construction detail of an evaporator.

front-seated, all outlets are closed and refrigerant is

trapped in the component (compressor or receiver). To

front seat a service valve, turn the valve stem clockwise

EVAPORATOR

as far as it will go. This puts the valve stem to the left

and tight against the front seat, and stops refrigerant

The evaporator (fig. 11-12) is a band or coil of

flow at the valve.

thin-walled tubing in a block of thin metallic fins. As

the refrigerant is passed through the coil, warm air to be

cooled is passed over the outside. Heat transfers from

WARNING

the outside air to the refrigerant through the fins and

metal walls of the coil. The heat passing to the

Never operate the compressor with the discharge

refrigerant causes it to vaporize. (Remember, R-22

service valve front-seated. This condition blocks the

vaporizes (boils) at -41F.) And, as the refrigerant

output of the compressor and causes its pressure to

vaporizes, it cools the coil, which cools the warm air

build up enough to become dangerous to personnel.

passing over it. The refrigerant exits the evaporator as a

Even if no explosion occurs, the compressor will

cool vapor at low pressure.

almost certainly sustain damage.

ACCESSORY COMPONENTS

BAC K - S E AT E D . -- T h e s e r v i c e v a l v e i s

back-seated for normal operation. In this position, the

There are various accessories that can be added to

refrigerant line to the system is completely open, and

the major components to provide either simplified

the servicing/gauge port is closed. To back seat a

maintenance or increased efficiency without changing

service valve, turn the valve stem counterclockwise as

the function of the refrigeration system.

far as it will go.

GAUGE

PORT

PLUG

VALVE

CAP

BACK

WASHER

SEAT

GAUGE

PORT

VALVE

PLUNGER

VALVE

STEM

VALVE

PACKING

GAS

ASf11013

GAS

FORWARD

LINE

LINE

SEAT

Figure 11-13.--Service valve.

11-14