2. Set the operating mode (selector valve) to

opened only when the suction developed by the

PUMP DOWN. (See figure 11-20.)

downward stroke of the piston is greater than the

vacuum already in the line. This vacuum pump can

3. Set the thermostats to the coldest temperature

develop a vacuum close to -30 inches of mercury, which

possible to hold the evaporator coils open.

can be read on the gauge mounted on the unit (fig.

4. Disconnect the ground wire of the hot gas

11-25). You will use the pump when it is necessary to

bypass valve. This de-energizes the valve to prevent

remove air and moisture from the system, a process

bypassing during pump down.

called evacuation.

5. Place a jumper wire on the contacts of the

Evacuating the System

low-pressure relay. Doing so cuts the relay out of the

circuit and keeps the compressor running during the

Evacuation is required to remove all traces of

procedure.

moisture that may have entered the system during

6. Monitor the suction gauge until it reads 5 psi.

maintenance. Moisture turns into vapor under a vacuum

At 5 psi, turn the selection valve to the start-ventilate

and must be removed from the system to prevent

position. This disengages the compressor.

freezing of expansion valves and blocking of

passageways. Moisture also contributes to the

7. Continue to monitor the suction gauge. It will

formation of hydrochloric and hydrofluoric acids in the

normally rise above 5 psi due to the refrigerant still in

system, which can cause corrosion and gumming of

the system. Repeat the pump down procedure until the

internal parts of compressors and piping.

system stabilizes at a maximum of 5 psi, but no lower

than 2 psi.

Whenever the system is opened, precautions must

be taken to prevent loss of refrigerant to the

8. When the system is stabilized at 2 to 5 psi, shut

atmosphere. There are two ways to contain the

down the engine.

refrigerant (gas and liquid). One way is to trap the

9. Close (front seat) the compressor discharge

refrigerant in the receiver (pumping down). The other

valve.

way is to remove it from the system by using a

refrigerant recovery unit, which removes the refrigerant

10. Close (front seat) the receiver inlet valve.

from the mobile air conditioner and stores it in external

11. Close (front seat) the compressor suction

tanks.

valve.

PUMPING DOWN.--The first step in evacuating

12. Remove the jumper wire from the low-pressure

the system is to pump it down by using the following

procedures:

13. Reset the thermostats back to their normal

1. Close (front seat) the receiver outlet valve.

operating positions.

That completes the pumping down part of the

procedure. This part of the procedure could be

performed by using a refrigerant recovery unit to

transfer the refrigerant to an external tank.

EVACUATING.--After the system has been

pumped down and the refrigerant is trapped in the

receiver, you can evacuate the system by using the

following procedures:

1. Connect the refrigerant manifold test set, as

shown in figure 11-26.

2. Ensure that the receiver inlet and outlet valves

are closed (back seated).

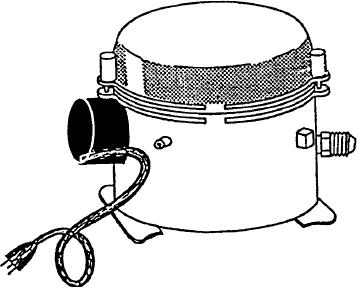

ASf11025

3. Ensure that the compressor suction and

discharge valves are closed to the service port (back

seated).

Figure 11-25.--Portable vacuum pump.

11-26