Adjustments

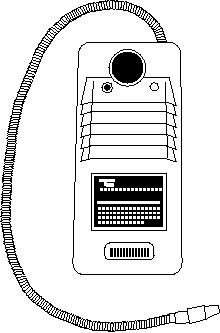

HALOGEN LEAK DETECTOR TEST.--The

use of a halogen leak detector is the most positive

The adjustments of the many valves and solenoids

method of detecting leaks in a refrigerant system (fig.

have one thing in common--they are very sensitive and

11-27). It is a portable, battery operated electronic leak

only one turn, or two at the most, is all that is required at

detector. It is capable of finding leaks as small as

a time. Then, the system has to run for a while until all

ounce per year as well as large leaks in areas where

readings stabilize. With this in mind, you can see that

background contamination may be present.

consulting the manual (with all of its tables of normal

The instrument features a variable frequency alarm

settings and relationship charts) is a necessity when

signal that gives an indication of the concentration of

performing maintenance on an air-conditioning

halogen gases (size of leak). It permits the operator to

system.

"home in" on the leak source without continually

Superheat is adjusted by the thermostatic expan-

readjusting the instrument for the changing ambient or

sion valve, which meters the amount of liquid entering

background contamination.

the evaporator coil. When adjusting the valve, turning

The sensing tip (Qutip) at the end of the probe is not

the valve stem counterclockwise two full turns

adversely affected by large amounts of refrigerant, as

increases superheat about 1 degree. Turning the stem

are vacuum-type halogen gas detectors. Recovery time

clockwise decreases superheat about 1 degree for each

after the probe is removed from a contaminated area is

two turns.

virtually instantaneous.

The temperature control, which senses outlet air

This instrument requires no warm-up period, and it

temperature, is a two-stage control. Each stage controls

is ready to use following a simple balancing procedure.

a solenoid valve that, in turn, feeds liquid refrigerant to

It is equipped with a dual length flexible probe, which

each section of the aftercooler coil. As delivered air

can be bent to permit the sensing tip (Qutip) at the end

temperature falls below the set point, the first stage of

of the probe to reach normally inaccessible areas.

the temperature controls actuates and closes one of the

two aftercooler liquid line solenoid valves. Set the

Always be sure your instrument is off when

temperature to meet the needs of your climate area and

changing tips. The battery voltage is amplified in the

to your cooling needs.

sensing tip (Qutip). Failure to turn the instrument off

when changing tips can result in a mild shock and

Other adjustments available to you are the

possible damage to the instrument.

compressor cylinder unloaders, the hot gas bypass

regulator, and the condenser fan speed regulator.

When leak detection is necessary, make sure the

You should follow the settings in the technical

following steps are taken before use:

manual to achieve maximum efficiency from your

air-conditioning system.

Testing for Refrigerant Leaks

The best time to test joints and connections in a

system is when there is sufficient pressure to increase

the rate at which the refrigerant is leaking from the

component. There is usually sufficient pressure in the

high-pressure side of the system; that is, in the

Thermal

condenser, receiver, and liquid line, including

xxxxx

Model No. 1947

dehydrators, strainers, line valves, and solenoid valves.

However, this is not necessarily true of the low-pressure

side of the system. Where there is very little pressure,

US SDLFIGGGLL

SDFGHJKLUYRE

you can increase the pressure in the low-pressure side

by bypassing the discharging pressure from the

condenser to the low-pressure side through the service

gauge manifold. Small leaks cannot be found unless the

ASf11027

pressure inside the system is at least 40 to 50 psi,

regardless of the method used to test.

Figure 11-27.--Halogen leak detector.

11-28