SAFETY PRECAUTIONS

Troubleshooting

Working on air-conditioners can be very dangerous

The following chart (table 11-5) details some of the

if safety precautions are not taken. The following safety

more common problems encountered in trouble-

precautions are mandatory to prevent injury to

shooting an A/M32C-17 mobile air-conditioner. Also

personnel working on or in the immediate vicinity of

listed are suggested ways to fix the problems. Some of

air-conditioning units.

the steps may seem complicated, but they are really

basic troubleshooting procedures with which you need

Use approved goggles or a face shield when

to become familiar. As always, for more detailed

handling refrigerants.

information, refer to the technical manual NAVAIR

Do not allow liquid refrigerant to contact the

19-60-87.

skin.

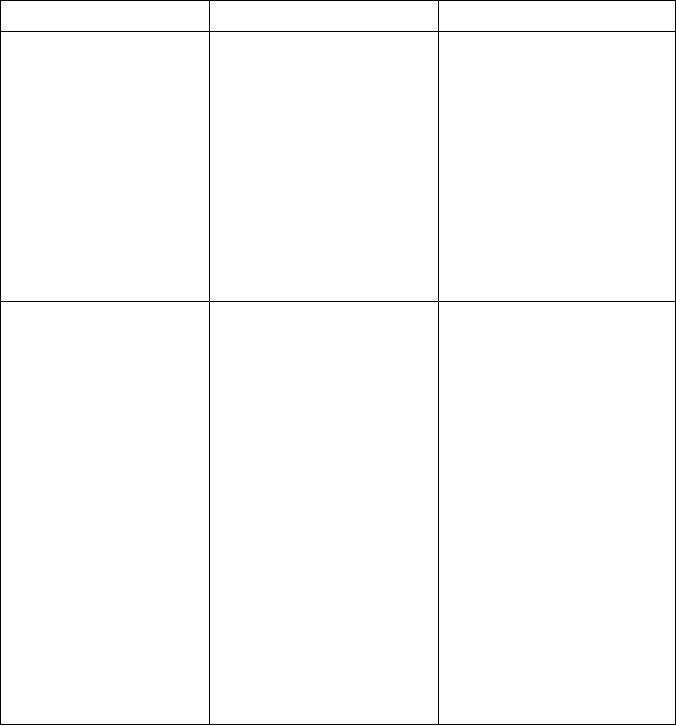

Table 11-5.--Troubleshooting the A/M32C-17

INDICATION

PROBABLE CAUSE

SUGGESTED REMEDY

A. Compressor fails to start

1. Electromagnetic clutch not 1. Replace or repair

operating

electromagnetic clutch.

2. Broken or sheared coupling

2. Replace coupling.

3. Seized compressor, locked 3.

Overhaul compressor.

or damaged mechanism

4.

Check for loss of refrigerant.

4. Suction pressure below

Repair leaks and recharge.

setting of low-pressure

5.

Refer to G below.

5. Discharge pressure above

6.

Check compressor oil level,

cut-in setting of

oil pressure, wiring and

high-pressure cutout switch

controls.

6. Oil failure switch cutout

B. Compressor

1. Low-pressure controller

1. Reset low-pressure cutout, or

"Short-Cycles"

differential set too close

replace.

2. High-pressure controller

2. Reset high-pressure cutout or

differential set too close

replace.

3. Reduced airflow. Iced

3. Clean or defrost evaporator

coils. Check filters and fan

drive.

a. Dirty air filter

4. Repair or replace valve.

b. Broken fan belt

5. Remove excess refrigerant or

c. Improper fan belt

purge noncondensible gas and

tension

check for leaks.

4. Leaking liquid line solenoid

6. Repair refrigerant leak and

valve.

recharge.

5. Overcharge of refrigerant or

7. Clean or replace strainer

noncondensible gas in

system

6. Insufficient refrigerant

7. Restricted drier strainer

11-33