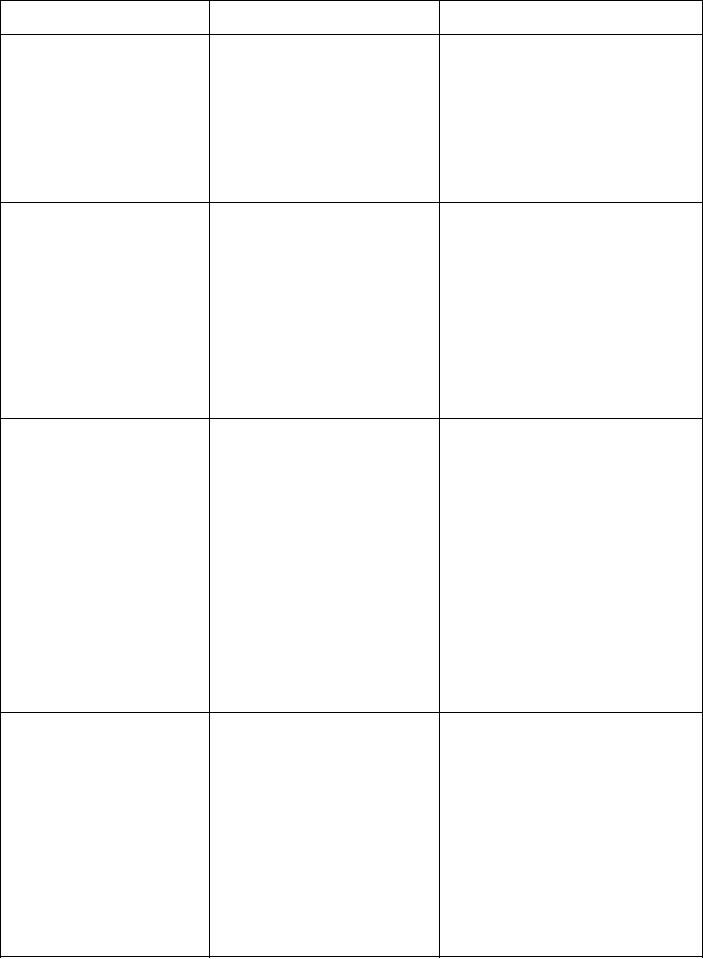

Table 11-5.--Troubleshooting the A/M32C-17--Continued

INDICATION

PROBABLE CAUSE

SUGGESTED REMEDY

1. Hydraulic pump belt broken 1. Check fan belt and clean exterior

G. Discharge pressure too

of condenser.

high

or condenser tubes dirty

2. Air or noncondensible gas in 2. Purge and check for leaks.

system

3. Remove excess.

3. Overcharge of refrigerant,

excessively hot condenser

and discharge pressure

1. Repair leaks and recharge.

H. Discharge pressure too

1. Lack of refrigerant--

low

bubbles in sight glass

2. Remove head. Examine valves,

and replace faulty valves.

2. Broken or leaking com-

pressor discharge valve(s).

3. Inspect and repair or replace

Suction pressure rises faster

unloaders.

than 5 lb/min after pressure

4. Remove and inspect valve.

shutdown

Replace if necessary.

3. Unloader(s) stuck open

4. Leaking hot gas bypass valve

1. Refer to C above.

I.

Suction pressure too high 1. Excessive load on

evaporator--compressor

2a. Check to be sure that remote bulb

runs continuously

is firmly in contact with suction

line.

2. Over-feeding of expansion

valve--abnormally cold

2b.

Check superheat setting of

suction line; liquid feeding

expansion valve.

back to compressor

2c.

Repair or replace expansion valve.

3. Expansion valve stuck

3.

Repair or replace valve.

open--abnormally cold

suction line; liquid feeding 4.

Remove head, examine valves,

back to compressor

and replace those found to be

inoperative.

4. Broken suction valves in

compressor

1. Repair leak and recharge.

J. Suction pressure too low

1. Lack of refrigerant--

bubbles in sight glass

2. Clean or replace strainer.

2. Clogged liquid line

3. Clean or replace valve.

strainer--temperature

4. Repair or replace thermostat.

change across strainer

5. Reset compressor capacity

3. Obstructed expansion valve

control range.

4. Thermostat stuck closed

5. Compressor capacity control

set too low--compressor

short cycles

11-35