CHAPTER 12

GAS TURBINE COMPRESSORS

INTRODUCTION

FUEL

SPARK PLUG

IGNITOR

Gas turbines are a familiar sight on the flight decks

AIR IN

of aircraft carriers and the flight lines of naval air

stations. They are most often tractor mounted aboard

ship and trailer mounted at shore commands. The

primary use of gas turbine engines is to provide

TURBINE

pneumatic power to start aircraft engines. The

p n e u m a t i c b l e e d - a i r p ow e r i s h i g h - vo l u m e ,

COMPRESSOR

low-pressure compressed air, which is used to operate

equipment that requires a high volume of air. This

NOZZLE

includes aircraft engine starter motors,

COMBUSTION CHAMBER

air-conditioning systems, and aircraft generator test

stands.

FUEL

As an AS, you are required to maintain and repair

gas turbine engines used in support equipment. The

prolonged life and operational readiness of the gas

turbine engine invariably depend upon the familiarity

maintenance personnel have with the equipment.

It is essential that you know the engine as

thoroughly as possible. You should know what it is

designed to do and how it fulfills that function. You

should also be familiar with normal operating details

of the engine, such as oil pressures, temperatures, fuel

pressures, flows, consumption, and exhaust gas

temperatures. You should be familiar with all of these

COMPRESSOR - CENTRIFUGAL - FLOW

(DOUBLE - ENTRY TYPE)

operating conditions from starting to idle, from idle to

ASf12001

load, and from load to shutdown of the engine.

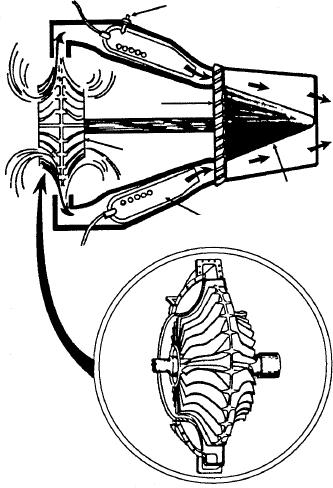

Figure 12-1.--Centrifugal-flow type engine.

DESCRIPTION AND PURPOSE OF GAS

advantages of the centrifugal type over the axial-flow

TURBINE ENGINES

type are as follows:

Simplicity of design and manufacture, thus

LEARNING OBJECTIVE: Identify the two

lower cost

types of gas turbine compressor engines.

Identify their various components.

Lighter weight

Basically, there are two types of gas turbine

Low starting power requirements

engines--the centrifugal-flow type and the axial-flow

type. (See figures 12-1 and 12-2.) By studying these

B e c a u s e t h e c e n t r i f u g a l - f l ow i s t h e m o s t

figures, you can see that the greatest single difference

commonly used in support equipment, the axial-flow

is in the compressor section. The construction features

will not be discussed. However, by understanding the

of the compressor (axial-flow or centrifugal-flow)

centrifugal-flow type, the axial-flow type can also be

determine the designation of the engine.

understood, since all other sections and components

except the compressor are very similar in design and

The centrifugal-flow compressor engine is the

most common engine used in support equipment. The

operation.

12-1