the turbine wheel at the proper angle to drive it. The

compressor, a n d t r e m e n d o u s ve l o c i t y i s a ga i n

high-velocity, high-energy exhaust gas flow drives the

imparted to it by the second stage impeller. It is then

turbine (hence the term gas turbine) at a very high rate,

directed into the second stage diffuser, where it is

providing the power to drive the compressor and

slowed down and its pressure further increased (second

accessories and to support pneumatic loads. After

stage compression) to approximately 37.5 psi.

passing through the turbine blades, the exhaust gases

From the second stage compressor, the air is

(still hot) pass out the tail pipe to the atmosphere. A

directed through a set of deswirl vanes where, as the

heat shield mounted on the turbine wheel end of the

term deswirl implies, the air is straightened out into a

b e a r i n g c a r r i e r p r eve n t s ex c e s s ive h e a t f r o m

smooth flow as it enters the turbine plenum chamber.

penetrating the turbine wheel shaft to the bearings.

Approximately 70 percent of the air entering the

Ventilation is provided within the enclosure by

turbine plenum chamber is used to support combustion

action of the aspirating exhaust duct that draws air

and for combustion chamber cooling, while the

through louvers located in the front and rear of the

remaining 30 percent is available as bleed air for

enclosure, and discharges it around the exhaust. Heat

operation of pneumatic equipment. When no air is

shields are provided to protect the battery and the oil

being bled from the engine, this 30 percent provides

tank. The battery heat shield, located between the

additional engine cooling, enabling the engine to

battery and the exhaust duct, is louvered. Aspiration of

operate at reduced temperatures under no-load

the duct pulls air through the louvers in the front panel,

conditions.

around the battery, through the louvers in the heat

Air enters the combustion chamber via small holes

shield, and out the exhaust.

or perforations in the flame tube or liner, where it is

combined with fuel and burned. The result of burning

Fuel and Bleed-Air Control System

the fuel is the rapid expansion of burning gases and

creation of a high-velocity, high-energy exhaust gas

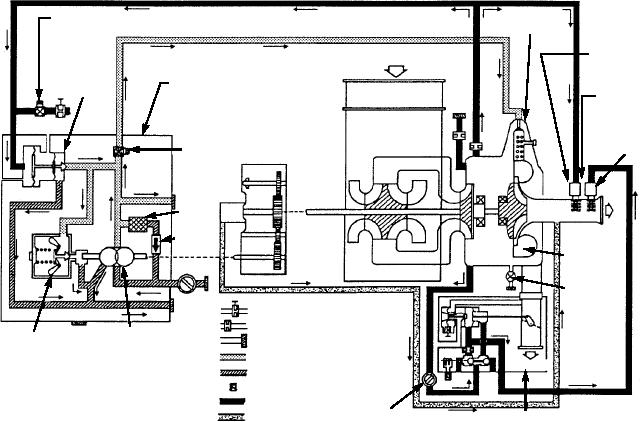

The fuel and bleed-air control system, as shown in

flow. This gas flow is collected in an assembly, referred

figure 12-6, functions automatically to maintain a

to as the torus, and directed through a nozzle ring

near-constant turbine operating speed under varying

surrounding the turbine wheel and onto the blades of

conditions of load. The system consists of fuel,

FUEL

ACCELERATION STABILIZER SOLENOID AND

ATOMIZER

ADJUSTABLE ORIFICE

COMPRESSOR AIR INLET

OVERTEMP

THERMOSTAT

PNEUMATIC

FUEL PUMP AND BLEEDING

GOVERNOR

CONTROL UNIT

TEMPERATURE

SENSING

LOAD

CONTROL

THERMOSTAT

FUEL

FUEL

FILTER

TURBINE

RELIEF

EXHAUST

VALVE

BLEED AIR

CHAMBER

TURBINE

PLENUM

ADJUSTABLE ORIFICE

DRAIN

ORIFICE

FUEL

MECHANICAL

CUSTOMER CONNECTION

PUMP

GOVERNOR

HIGH PRESS FUEL

BLEED AIR

LOW PRESS FUEL

FUEL DRAIN LINE

CONTROL AIR

COOLING AIR

DIFFERENTIAL

ASf12006

UNLOADING - AIR

AIR PRESSURE

SHUTOFF VALVE

REGULATOR

Figure 12-6.--Fuel and bleed-air control system.

12-6