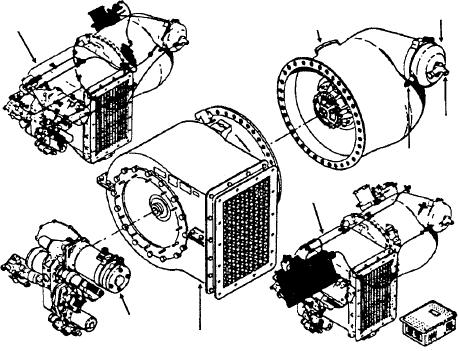

COMBUSTION

CHAMBER

CAP

TURBINE

PLUMBING

SECTION

SYSTEM

FUEL

ATOMIZER

PLUG

ELECTRICAL

SYSTEM

ACCESSORY

SECTION COMPRESSOR

SECTION

ASf12004

Figure 12-4.--Major sections of a gas turbine compressor (GTC-85).

Compressor Section

FUNCTIONAL SYSTEMS

This section provides a source of compressed air

Before you attempt to operate a gas turbine unit,

for combustion, cooling, and pneumatic power in the

you should have a knowledge of the different systems

form of bleed air.

and the function performed by each. In the gas turbine

unit there are four main functional systems, which are

The ambient air is moved by the first and second

listed as follows:

stage impellers, and is directed through diffusers that

Airflow

are mounted directly after the impellers. Compression

is accomplished by the diffusers due to their divergent

Fuel and bleed-air control system

shape.

Lubrication system

The impellers are mounted on a common shaft.

The ends of impellers are splined internally to receive

Electrical system

the drive shafts, which connect the compressor to the

accessory drive shaft and connect the turbine to the

Airflow

compressor.

In figure 12-5, note that the rotation of the

Power Turbine Section

compressor creates a low-pressure area at the inlet side

of the unit. This draws air through the oil cooler into the

The turbine section is the power section, which

first stage compressor plenum chamber (air supply

provides driving power for the entire unit. The major

chamber). Also note that the first stage of the

parts of this section are the turbine wheel, turbine

compressor is constructed with a dual-entry; this is

plenum, combustion chamber assembly, and nozzle

necessary to provide the large volume of air that is

a s s e m b l y. A i r, w h i c h h a s b e e n t a ke n i n t o t h e

required for engine combustion and cooling and for

compressor, is routed to the combustion chamber

supplying pneumatic power.

section where it is mixed with fuel and ignited. As the

fuel-air mixture is burned, the gases expand rapidly,

As air is drawn into the first stage of the

increasing the velocity of the gas as it is exhausted to

compressor, tremendous velocity is imparted to it by

the rear through the nozzle assembly. From the nozzle

the first stage impeller. The air is then directed into the

assembly, these hot gases are directed onto the blades

first stage diffuser, where it is slowed down and its

of the turbine wheel, turning the turbine at a very high

pressure increased (first stage compression) to

speed. In turn, the turbine drives the compressor and

approximately 18 psi. It is then directed through

the accessory drive assembly.

interstage ducts into the second stage of the

12-4