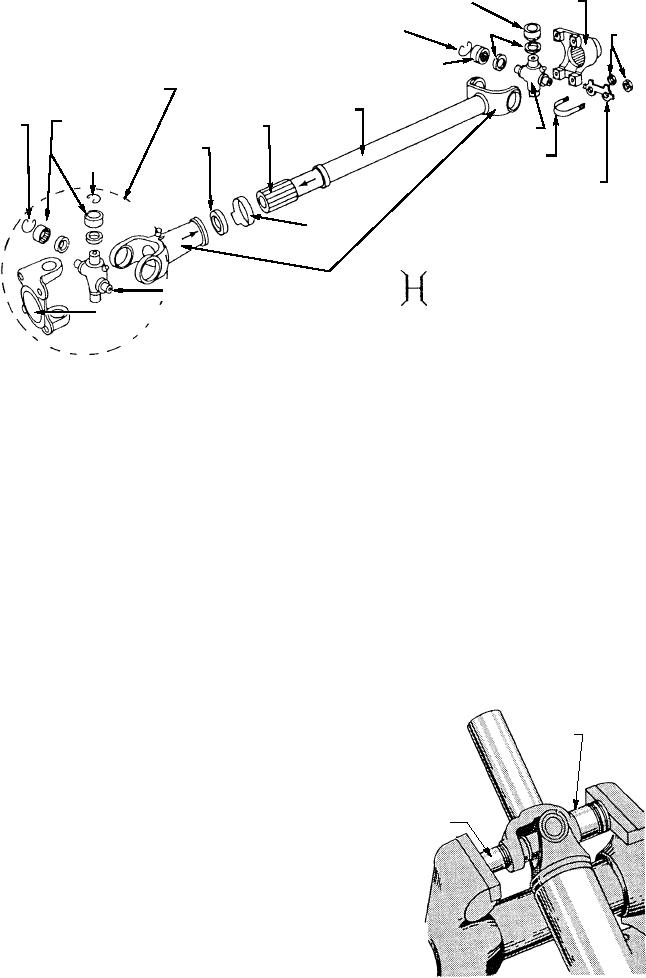

FLANGE

ROLLER BEARING

YOKE

OIL

SNAPRING

SEAL

NUTS

UNIVERSAL

ROLLER BEARING

JOINT

ASSEMBLY

PROPELLER

SHAFT

SLIP JOINT

ROLLER

SNAPRING

SPLINE

JOURNAL

BEARING

CORK

GASKET

U-BOLT

SNAPRING

LOCK PLATE

OIL

SEAL

DUST

CAP

FIXED YOKE

ASSEMBLED IN

JOURNAL

SPLINED SLIDING YOKE

SAME PLANE

FLANGE YOKE

ASf02081

Figure 2-81.--Propeller shaft assembly.

spider fit into bearings in the end of the driving shaft

transmission is some distance from the differential.

yoke, and the other two arms (trunnions) are assembled

Solid shafts are usually used on tow tractors because

in the end of the driven shaft yoke. When the two shafts

the shaft is very short.

are at an angle to each other, the bearings in the yokes

The slip joint is necessary because the movement

permit the yokes to swing on the trunnions with each

between the transmission and the differential requires

revolution. (Universal joints may have roller bearings

that the propeller shaft be able to shorten or lengthen

around the trunnions.)

itself. On vehicles having rear springs, the differential

Slip joints and universal joints require little

moves up and down as the rear wheels move over

maintenance, except for those that need lubrication

uneven surfaces. This up and down movement

where fitted with grease fittings. Others may be factory

lengthens and shortens the distance between the

packed with grease and not need lubrication. Repair is

transmission and the differential. On vehicles such as

normally limited to removal and replacement of worn

tow tractors that have no rear springs, the slip joint is

bearings, which are pressed out and replaced with new

necessary because the distance between the

ones, as illustrated in figure 2-82.

transmission and the differential still increases and

decreases when the vehicle moves over uneven

surfaces. Vibration of the engine on its shock mounts

RECEIVER

SOCKET

and expansion and contraction also necessitate a slip

joint.

Because the differential is situated below the level

of the transmission, universal joints are necessary to

DRIVER SOCKET

permit the change of direction of drive. The usual type

of slip joint consists of a splinted shaft that fits into a

splinted sleeve, as shown in figure 2-81. The splints

permit the continuing transmission of power as the

sleeve moves back and forth on the shaft. A universal

joint is essentially a double-hinged joint consisting of a

Y-shaped yoke on the driven shaft, another Y-shaped

yoke on the driving shaft, and a cross-shaped member

ASf02082

called the spider. Figure 2-81 shows a common

Figure 2-82.--Universal joint removal.

universal joint. Two of the four arms (trunnions) of the

2-71