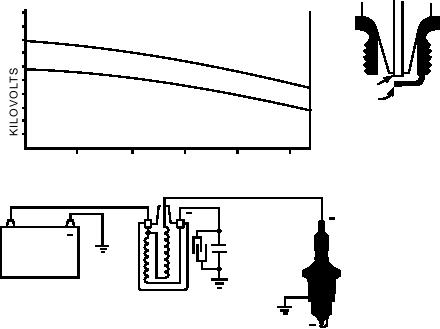

If the coil is connected so that polarity is reversed

battery's terminal posts and cables. Connections must

(spark plug center electrode positive), up to 40 percent

be clean, tight, and free of corrosion. Check for obvious

more voltage is required to fire the plugs (fig. 6-47).

damage in the primary wiring, such as broken or loose

This condition could result in hard starting, missing,

wires, or frayed insulation. All connections must be

and eventual coil failure.

clean and tight.

Pull the ignition coil's high voltage lead out of the

System Tests

coil tower. Check the tower for signs of corrosion or

burning. If it is corroded, clean it with a round brush or

There is a quick test you can use to try to localize

sandpaper wound around a pencil. Examine the tower

problems with the ignition system. First, remove the

carefully for any sign of flashover (high-voltage current

secondary coil lead from the distributor cap. Hold it

leaving the intended path and jumping down, or around,

approximately 3/16-inch from ground while you crank

directly to ground). Flashover can be caused by

the engine and observe the spark. A bright blue spark

moisture or dirt on the coil extender, a corroded tower

indicates proper operation of the primary circuit and the

interior, or by failing to have the high voltage lead

secondary winding of the ignition coil. That means that

pushed fully into the tower. If flashover has cracked the

troubleshooting can be limited to the distributor cap,

tower or left a burned path (carbon track), replace the

rotor, spark plug leads, and spark plugs. A yellow

coil. Check for correct coil polarity. The coil must be

spark, on the other hand, would indicate that the

connected into the primary circuit so that the positive

malfunction is in the primary circuit or the secondary

and negative markings of the coil correspond to the

winding of the ignition coil.

battery connections. In a negative grounded system, the

PRIMARY CIRCUIT TESTS.--Three basic

negative terminal of the coil must be connected to the

voltmeter tests can be made to isolate high resistance

distributor where it is grounded through the breaker

areas or components in the primary circuit. They are

points. By connecting the coil in this manner, the center

shown in views A, B, and C of figure 6-48.

electrode of the spark plug assumes a negative polarity.

NOTE: The voltage readings and test connections

It takes less voltage to cause electrons to move from

used here are for a 12-volt, negative ground system.

a hot to a cold surface. Since the center electrode of the

Always use the test specifications given by the

plug is always hotter than the side (ground) electrode,

manufacturer for any specific system.

current flow must be from the hot center electrode to

the cooler side electrode. By giving the center electrode

Battery-to-Coil Test.--Connect the voltmeter as

a negative polarity, current flows in this manner.

shown in figure 6-48, view A. Connect a jumper wire

20 TO 40% MORE VOLTAGE IS REQUIRED

WITH POLARITY REVERSED

REQUIRED

VOLTAG

E POS

ITIVE

POLA

REQUIRED V

RITY

OLTAGE

NEG AT

IVE P

HOTTER

OLAR

ITY

COOLER

ELECTRONS WILL MOVE

FROM A HOT OBJECT TO A

COLDER OBJECT AT A

LOWER VOLTAGE

ENGINE R P M

VOLTAGE REQUIRED AT SPARK PLUG

+

+

BATTERY

COIL

THE PRIMARY TERMINALS OF THE COIL MUST

BE CONNECTED SO THAT THE POLARITY MARKINGS

CORRESPOND TO BATTERY POLARITY.

ASf06047

Figure 6-47.--Correct coil polarity and current flow for a negative grounded system.

6-42