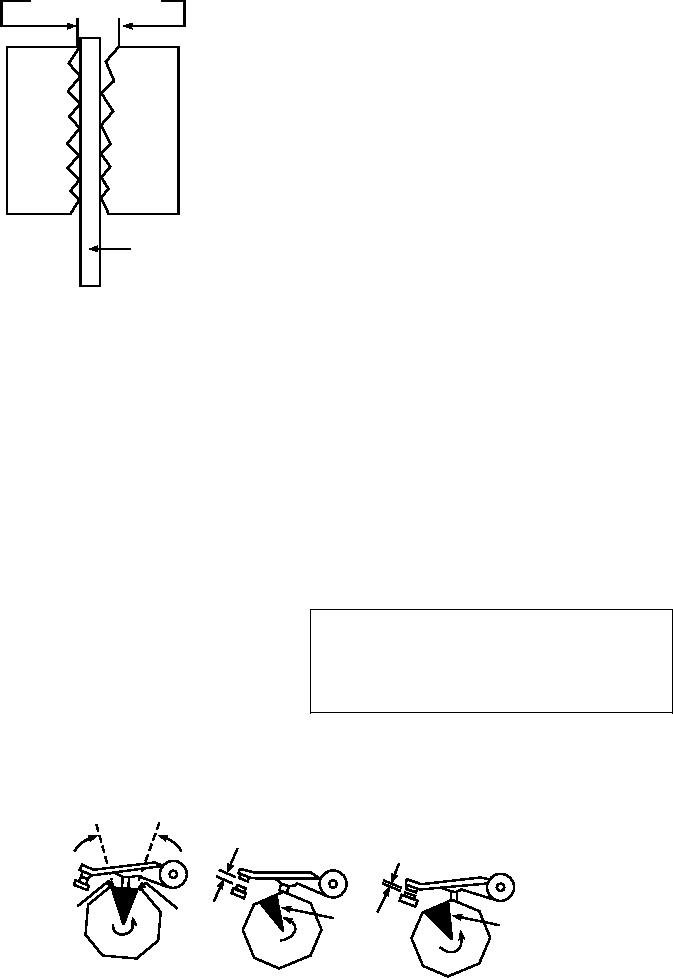

ACTUAL GAP .022

If the point gap decreases, dwell increases; if point

gap increases, dwell decreases. Point gap and dwell are

inversely proportional.

Once the point gap has been set, the breaker arm

spring tension should be checked. Use an accurate

ounce scale. If the pressure is excessive, rapid wearing

of the rubbing block can cause the point gap to narrow,

retarding the engine timing and increasing the dwell.

Too low a pressure can cause the points to bounce,

creating a high-speed miss.

With the rubbing block positioned on the low point

.015

between cam lobes, hook the scale at the contact point

FEELER

GAUGE

edge. Pull at right angles to the moveable arm, and

check the pressure just as the points separate. Compare

ASf06050

Figure 6-50.--False setting given by feeler gauge for used

to the manufacturer's specifications. If the pressure is

points.

incorrect, refer to the applicable maintenance manual

for adjustment procedures. Ensure that all wires are

correctly connected and clear of all moving parts.

gap is excessive, saturation time for the coil is reduced

Remove rags that were used to plug openings.

and high-speed missing occurs.

Apply a thin coat of high-temperature grease to the

The gap for new points may be set initially with a

breaker cam. Do not use engine oil or low-temperature

feeler gauge. This is done by turning the breaker cam

grease as it will be thrown off and onto the points. On

until the point rubbing block is on the highest point of

distributors equipped with a felt wick oiler under a

the cam lobe, and then moving the stationary point plate

lift-off rotor, moisten with engine oil (3 to 5 drops).

until a feeler gauge of the correct thickness is a snug fit

Lubricate the point pivot pin and bushing, the

between the contacts. Refer to the manufacturer's

centrifugal advance mechanism, and the breaker plate

specifications for the correct gap.

bearing surfaces very lightly with engine oil. If an

As shown in figure 6-50, however, used points

outside oiler is provided, apply 5 to 7 drops of engine

cannot be gapped accurately with a feeler gauge. The

oil.

gauge measures between the high spots while the actual

point opening is much greater. Note that a .015 feeler

gauge is a snug fit, but the actual gap is .022. The best

CAUTION

method of obtaining the necessary accuracy for setting

used points is the use of a dwell meter.

Lubricate distributor parts sparingly. Lubri-

cant on the points may cause rapid burning.

Dwell (often called cam-angle) refers to the

distance in degrees of breaker cam rotation that the

breaker cam revolves from the time the points close

If you have a distributor test machine, use it to

until they are opened again (fig. 6-51). The dwell for

check the distributor for dwell, vacuum and centrifugal

any given set of breaker points is controlled by the point

advance, point bounce, bent shaft, worn bushings, worn

gap, so the two must be considered together.

breaker cam, etc.

DWELL

LARGE GAP

SMALL GAP

POINTS

POINTS

SMALL

LARGE

OPEN

OPEN

DWELL

DWELL

CORRECT DWELL/

CORRECT GAP

ASf06051

Figure 6-51.--Relationship of dwell and point gap.

6-46