View (G) shows a plug from an engine that ran

dwell. It should not have changed more than 3 degrees.

normally. The damage to the plug was caused by the

If you note a greater change, the distributor has worn

mechanic attempting to bend the center electrode.

bearings or a worn cam and should be removed for

repair.

View (H) shows a plug from an engine that had a

foreign object in the combustion chamber.

SPARK PLUGS.--When plugs receive periodic

cleaning and gaping, they will function better and last

The plugs shown in views (F), (G), and (H) cannot

longer. Spark plug wires should be carefully removed

be reused, but the others can be reconditioned.

by grasping them close to their terminals for the pull.

Before you attempt to clean a plug, remove oily

Do not jerk them from the spark plug terminal. Loosen

deposits with an approved solvent. This is to prevent the

each plug one or two turns, and then use low-pressure

cleaning material from soaking and packing into the

compressed air to blow out any dirt around the spark

area around the center electrode insulator.

plug hole. This prevents foreign matter from entering

the cylinder.

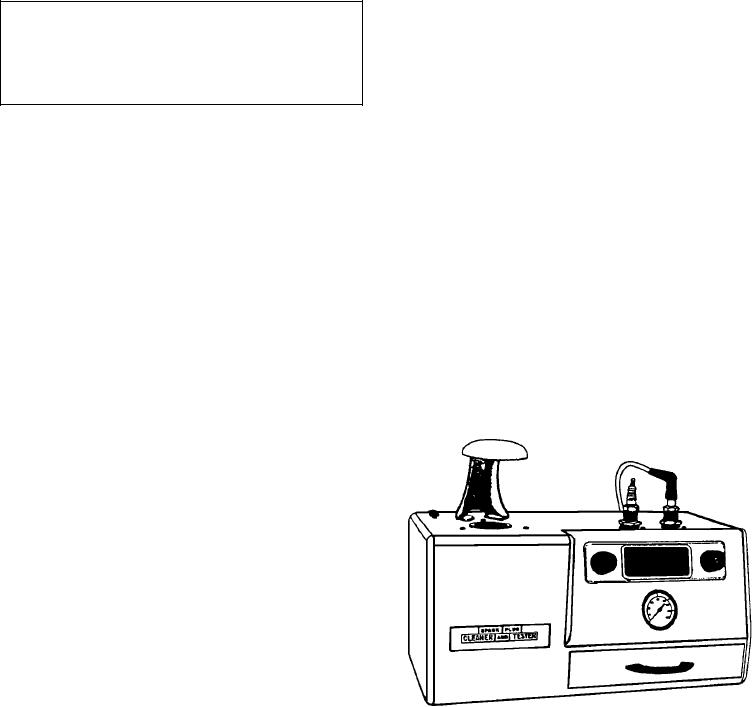

A machine of the type shown in figure 6-53 is used

to clean (sand blast) and test spark plugs.

Following the manufacturer's operating instruc-

WARNING

tions, clean the plugs, blasting only long enough to

Always wear safety goggles when working

remove the deposits. Prolonged blasting damages the

with compressed air.

center electrode insulator.

Once cleaning is completed, the electrodes must be

Remove the plugs and ensure that the gaskets

filed clean and square. The machine blast does not

(where used) are also removed. As you remove the

clean this area. If the electrodes are not filed clean, the

plugs, keep them in order so that any peculiar condition

required voltage remains high and the plug may

of any plug can be related to a specific cylinder.

misfire.

The plugs shown earlier in figure 6-49 illustrate

Use a fine cut point file to file the end of the center

some of the plug conditions that may be encountered.

electrode flat. This produces clean, sharp edges that

The cause for each is discussed below.

improve plug performance. Remove only enough metal

to clean and square the electrodes.

View (A) shows a plug from a mechanically sound

engine, running at the correct temperature. Some

Use a round wire gauge (not a feeler gauge). Set the

deposits, light tan or gray in color, are present, but there

gap to the manufacturer's specifications by bending the

is no evidence of burning. Some gap growth has

side electrode.

occurred, but not in excessive amounts.

Testing spark plugs outside the engine can be very

View (B) shows a plug from an engine having

misleading. There is no true relationship between firing

excessive combustion chamber deposits. This is most

prevalent in engines operated at slow speeds and in

start-stop driving.

View (C) shows a plug from a cold running engine.

The deposits are unburned fuel.

View (D) shows a plug from an engine that was

running too hot due to over-advanced timing or to

cooling system blockage.

View (E) shows a plug from an engine using

excessive amounts of oil. The plug is drowned in oil

that was bypassed through the rings or valve guides.

View (F) shows a plug from an engine with severe

preignition. Preignition can be caused by an overheated

plug, a piece of glowing carbon, a hot valve edge, etc.

ASf06053

The damage shown is a result of temperatures in the

combustion chamber in excess of 2,700F.

Figure 6-53.--Spark plug cleaning and testing machine.

6-48