gasket too much, the shell may become distorted and

a plug in compressed air at room temperature (which is

damage the insulator.

the condition in the testing unit) and firing a plug in an

operating engine. In the operating engine, voltages are

ELECTRONIC IGNITION SYSTEMS.--As

higher, air-fuel mixtures are present, and the high

more modern and versatile SE is introduced into the

temperatures in the cylinders aid ignition. If these

fleet, electronic ignitions used in units employing

factors are kept in mind, spark plugs can be

gasoline engines have become more common. Most

successfully tested.

technicians will agree that the conventional (contact

Do not discard plugs that show a bluish light just

point/condenser) ignition system was the weakest

above the shell while they are being tested. This is a

link in the normally aspirated gasoline engine's

corona discharge caused by the presence of a

dependability chain. And although transistorized

high-tension field. It does not affect plug performance.

ignition has been around for years, it has normally been

Make sure the insulator is clean and dry before testing.

limited to high-performance automobiles and civilian

If a spark comes through the insulator to the plug shell,

equipment. But the dependability of the electronic

it is an indication that the insulator is cracked.

ignition has been proven, and it is becoming more

Sometimes this crack is hidden inside the shell where it

common in support equipment.

cannot be seen. In many cases, movement of the

Because conventional contact points burn easily

insulator can be detected by hand pressure.

and can handle only a limited supply of high voltages,

When you replace plugs, it is important that you

there were disadvantages in the conventional system. If

select replacement plugs with the proper heat range.

a higher primary current could be used without fear of

Check the manufacturer's manual to determine the most

burning the contact surfaces, then a higher secondary

suitable spark plug heat range for the engine. In special

voltage could be induced. Early transistor ignition

cases (or when the proper plug cannot be obtained),

systems used the contact points to trigger the

check with your supervisor to determine which is the

electronics within the module. With that design, the

best plug available for the particular engine.

points were not required to carry the primary's high

current flow, but they were subjected to rubbing block

When you install spark plugs, always use new

wear, which directly effected the saturation of the coil

gaskets, if gaskets are required. A gasket performs two

and the secondary ignition timing.

important functions. It maintains a gastight seal

between the plug and its seat, and it conducts heat from

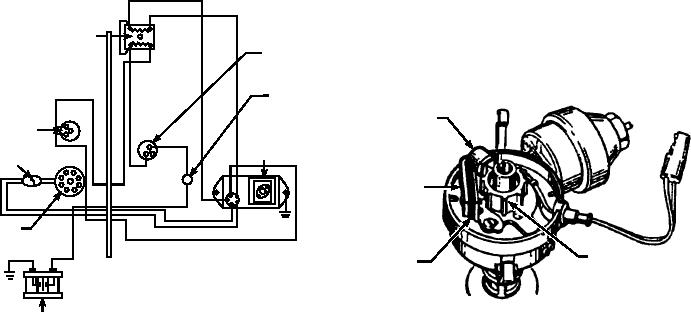

The transistor ignition system, shown in figures

the electrode tip to the engine block.

6-54 and 6-55, is used in the JG40 shop tractor. The

system is solid-state, which results in longer lasting

When you install spark plugs, use a torque wrench

plugs, less engine misfire under load, longer periods

and tighten them to the torque specified by the engine

between tune-ups, easier starting in the fleet

manufacturer. If you do not seat the gasket tightly, the

environment, and overall lower emissions. The ignition

spark plug becomes overheated. If you flatten the

system is a Chrysler Corporation design, and a

complete tester for the system is available through

Chrysler representatives. However, the theory is

relatively simple, as are the basic troubleshooting

_

BALLAST RESISTOR

procedures.

IGNITION

SWITCH

AMP

METER

PICKUP COIL

+

COIL

CONTROL

DISTRIBUTOR

UNIT

DUAL LEAD

CONNECTOR

POLE PIECE

DISTRIBUTOR

PERMANENT

_

ASf06054

+

RELUCTOR

MAGNET

ASf06055

BATTERY

Figure 6-55.--Distributor used with transistorized ignition

system.

Figure 6-54.--Electronic ignition system.

6-49