Types of Starter Drives

Starting Motor Construction

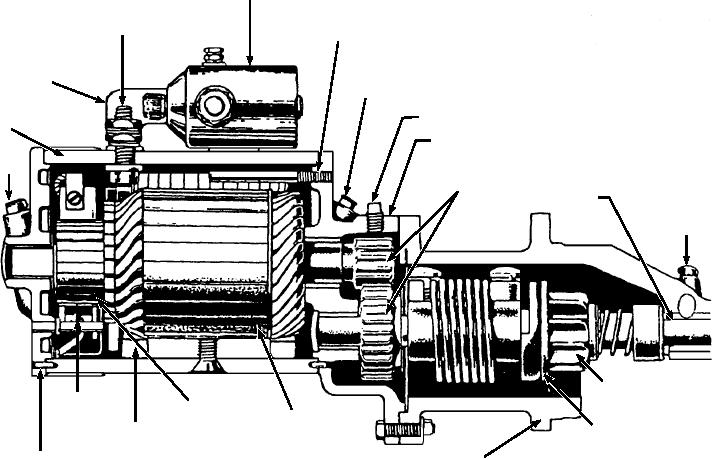

A starting motor uses a gear reduction to transmit

A sectional view of a heavy-duty starting motor is

its cranking power to the engine. The method most

shown in figure 6-66. This starter employs a magnetic

commonly used to obtain this gear reduction is a large

switch to control the starter, a reduction gear driving

diameter ring gear on the engine flywheel and a pinion

head, and a Bendix drive. Except for the drive end and

gear of much smaller diameter on the starting motor

control mechanism, the general construction charac-

armature shaft. In operation, the pinion engages and

teristics of the starting motor are similar to the dc

drives the ring gear, which turns the engine. The ratio

between the pinion and ring gear is different on engines

The connections and arrangements of the armature

of different sizes and horsepower. It is usually between

coils are such that current is flowing in all the coils at

10:1 and 16:1. The starting motor armature revolves 10

the same time (series wound). This allows each coil to

to 16 times for each revolution of the engine flywheel.

add its turning effort to the other coils. They work

When the pinion is engaged with the ring gear, the

together to turn the motor armature.

starting motor turns 2,000 to 3,000 rpm. This turns the

The field windings are used to increase the strength

engine at speeds up to 300 rpm. During operation, the

of the magnetic field, and thereby increase the power of

engine may reach speeds of 3,000 to 4,000 rpm. If the

the motor. The field windings are connected in series

pinion should fail to disengage from the ring gear after

with the brushes and armature windings. The current

the engine is started, the starting motor could be rotated

that flows through the field windings also flows

by the engine at speeds up to 64,000 rpm. This high a

through the armature windings. A heavy conductor is

speed throws the windings from the slots in the

used in the field and the armature so the resistance of

armature and the segments from the commutator. To

the motor windings is very low. This permits an

prevent this, various methods of engaging and

extremely large current flow, and the motor develops

disengaging the pinion with the ring gear have been

high torque.

devised.

MAGNETIC SWITCH

TERMINAL

THRU BOLT

CONNECTOR

OILER

GREASE PLUG

COVER

BAND

GEAR HOUSING

OILER

REDUCTION

BRONZE

BEARING

OILER

GEAR

BRUSH

COMMUTATOR

ARMATURE

BENDIX DRIVE

FIELD COIL

DRIVE

ASf06066

HOUSING

COMMUTATOR

END FRAME

Figure 6-66.--Sectional view of a heavy-duty starter.

6-54