of tools and material, location of next higher level of

Cleaning is accomplished by the use of a .38

maintenance, and operational needs. To the extent

caliber wire bore brush and a small amount of Neats

possible, all repairs should be made locally.

or Vaseline. After using the wire brush to remove dirt

and corrosion in the contacts, wipe them clean with a

REPAIRING POWER CABLES

rag. To ensure all dirt and corrosion have been removed

and that no parts of the rag remain in the contacts,

The power output cables that carry current to start

inspect each contact after wiping.

or service aircraft can only function if they are properly

Special tools for working on cables are shown in

constructed and maintained. Improper and

figure 7-60. The rod is used to pull the conductor so it

nonstandard procedures used in the assembly or repair

will be properly seated in the plug. The contact holding

of cable assemblies and attachable plugs can lead to

key allows the hex rod to turn without twisting the

premature failure and possible safety hazards.

contact. Torque of the contacts to the conductors is 70

At the local level, repair is limited to the attachable

in-lb. and 50 in-lb for control contacts.

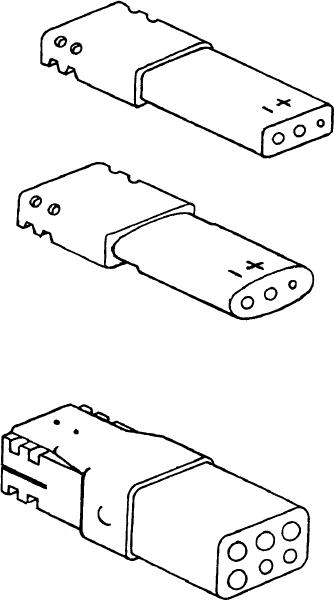

plugs (fig. 7-59). Such procedures include cleaning,

torquing, and repairing or installing new conductors

As noted, proper tools and standardized

and contacts. If the cable itself is cut or worn, it must be

procedures are a must for this job. Correct tinning and

replaced. You are not authorized to tape or splice a

crimping procedures are outlined in Intermediate

damaged cable.

Maintenance Instructions for Repair and Assembly of

External Power Cables and Attachable Plugs ,

MS 25487

NAVAIR 17-1-116, as well as the proper steps for

D. C. JET STARTING

replacing a damaged plug.

ATTACHABLE PLUG HEAD

Q7-26. What action should you take for repairing a

cut or worn power cable?

1.

Tape it with electrical tape

2.

Splice the damaged area

3.

Replace the worn cable

4.

Solder a connector over the worn area

MS 25488

and insulate it with heat shrink

D. C. SERVICING

ATTACHABLE PLUG HEAD

Q7-27. Which of the following manuals should you

use to repair an external power cable?

1.

NAVAIR 17-1-110

2.

NAVAIR 17-1-116

3.

NAVAIR 17-1-125

4.

NAVAIR 17-1-129

ELECTRICAL LOAD BANK

LEARNING OBJECTIVES: Identify the

MS 25486

components of electrical load banks. Identify

A. C. SERVICING

procedures for troubleshooting and

ATTACHABLE PLUG HEAD

maintaining electrical load banks.

The electrical load bank or dummy load, as it is

often referred to in the fleet, is designed to apply ac and

dc test loads to all types of 400-Hz and 28-volt dc

power plants. The load bank can also test a motor

generator set like the MMG-1A. It is designed for

shore-based or shipboard use. Most AS personnel

ASf07059

probably recognize this unit as the MLB-1A. With a

Figure 7-59.--Models of attachable head plugs.

new manufacturer, however, the designation has

7-51