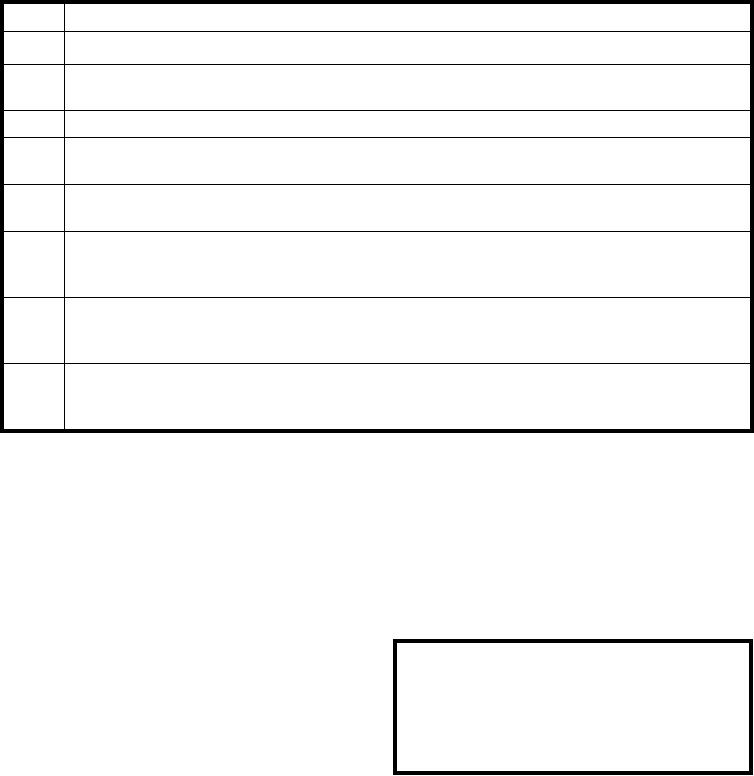

Table 10-3.--The Storage Tank Relief Valve Test

Step

Action

Ensure all control valves on the LOX cart are closed to start the test.

1

Open the transfer tank fill line shutoff valve (LV-2) and the transfer tank vent line shutoff valve

(GV-3) to fill the transfer tank.

2

When the tank is full, close the transfer tank fill line shutoff valve (LV-2).

3

Slowly open the transfer tank pressure buildup valve (GV-5) to build pressure in the transfer and

storage tanks.

CAUTION: Monitor the storage tank pressure gauge (P-1) constantly while operating the transfer

tank pressure buildup valve. Do not allow the supply tank pressure to go above 58 psig.

4

Raise the storage tank pressure slowly to 57 psig. The relief valve RV-1 should open somewhere

between 45 and 55 psig. If RV-1 does not open, a faulty component is indicated and must be

replaced.

5

After evaluating the storage tank relief valve, empty the transfer tank by opening the storage tank

vent shutoff valve (GV-6), the transfer tank fill line shutoff valve (LV-2), and the transfer tank

pressure buildup valve (GV-5).

6

When the transfer tank liquid level gauge (LG-2) indicates that the transfer tank is empty, close the

transfer tank fill line shutoff valve (LV-2), and the transfer tank pressure buildup valve (GV-5).

Leave the storage tank vent shutoff valve (GV-6) open.

enough pressure is bled off, the valve should reseat

THE

S T O R AG E

TA N K

PIPING

itself. Table 10-3 lists the steps in the procedure for

TEST.--When the storage tank piping is pressurized,

testing the relief valve on the storage tank. Procedures

you can use the storage tank piping test to check it for

for testing other relief valves are similar.

leaks. This test is often called a bubble test. (See table

10-5.)

If a relief valve is faulty, the cart should be relieved

of pressures and emptied of LOX prior to replacement

When leaks are detected, repair, if possible, by

of the valve.

tightening plumbing joints and/or valve packing.

After you disconnect the flexible tubing, unscrew

CAUTION

and remove the relief valve. To purge the piping,

connect a source of dry nitrogen gas (50 psig

Do not tighten joints or flanges while the tank is

minimum) to the storage tank fill coupling. Turn on the

under pressure, while LOX is present in the piping,

nitrogen to blow out the line. After securing the

or while the temperature of components is below

nitrogen gas and removing it from the fill coupling,

freezing (32F/0C).

install the replacement valve and reconnect the flexible

tubing.

NOTE: Use anti-seize tape on all pipe threads;

Troubleshooting

start tape at the third thread to prevent contamination.

Troubleshooting is a fine art. But, there are tools to

T H E E VA P O R AT I O N L O S S R AT E

assist you. Table 10-6 describes troubles, probable

TEST.--Another important test is the evaporation loss

causes, checking procedures, and remedies for

rate test. (See table 10-4.) This test is used to determine

repairing LOX carts. Keep in mind that no LOX cart

if a LOX cart is experiencing an unacceptable rate of

should be disassembled just to look for a problem. This

loss due to evaporation.

is true because of the high state of cleanliness required,

If the LOX cart fails the test, it is turned in for depot

and the ever present risk of contamination. So, before

repair. The Aviation Support Equipment Technician

removing components from a LOX cart, you must be as

sure as possible that you know the cause of the

performs NO repairs on the storage tank.

10-14