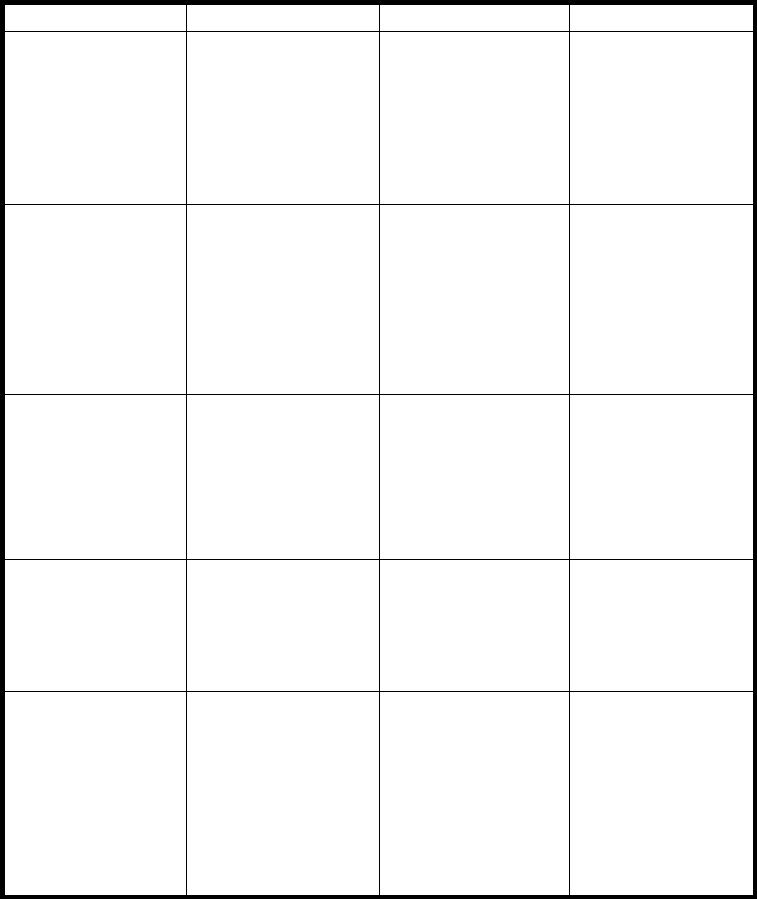

Table 10-6.--Troubleshooting Chart

Trouble

Probable Cause

Checking Procedure

Remedy

Excessive frost or

Automatic opening of

Wait to see if condition is

Abnormal condition will

condensation on lines

relief valve.

temporary

disappear.

Tank not level. Piping end

Visual.

Level tank, or put piping

down.

end up.

Valves leaking.

Check for escaping gas.

Repair or replace.

Vacuum deterioration.

Check evaporation loss

Locate and repair leak,

rate.

and re-evacuate tank.

Burst disc fails to blow

This is a dangerous

Check lines for foreign

Reduce pressure by

above rated pressure

condition. Lines are

material. Check setting of

opening vent valve. Clear

obstructed by foreign

pressure relief valve.

or thaw lines. Replace

material or ice. Also, the

relief valve. Purge entire

applicable pressure relief

system.

valve has failed to operate.

Wrong burst disc

Compare with

Replace with correct disc

assembly.

replacement disc

assembly.

assembly.

Pressure relief valves do

Pressure gauge faulty or

Check calibration.

Perform calibration

not open above rated

incorrectly calibrated.

procedures. If gauge

pressure

cannot be calibrated,

replace.

Valve faulty or incorrectly

Build up tank pressure

Replace relief valve.

set.

and recheck valve.

Valve frozen.

Visual or manual.

Thaw valve.

Pressure relief valves

Pressure gauge faulty or

Check calibration.

Perform calibration

open at less than rated

incorrectly calibrated.

procedures. If gauge

pressure

cannot be calibrated,

replace.

Relief valve faulty or

Build up tank pressure

Replace relief valve.

incorrectly set.

and recheck valve.

Excessive relief valve

Ice in valve seat.

Bubble check relief valve

Warm valve to ambient

leaking below reseal

outlet.

temperature.

pressure (36 psig for P/N

22385, 54 psig for P/N

22387, and 71 psig for

P/N 22386 and 22386-1)

Foreign material or object

Bubble check relief valve

Replace relief valve.

lodged in valve.

outlet.

Faulty relief valve.

Replace relief valve.

10-16