With the vent valve closed, use the pressure build-up

contamination, the container must be drained and the

LOX wash test repeated.

coil to pressurize the container to 30 to 40 psig, and

then dump the LOX. Repeat this procedure for a total

PURGING.--When repeated LOX washing fails

of three cycles.

to decontaminate a LOX trailer, the trailer is shipped to

a depot-level activity that has the proper equipment to

Collecting a Sample for Testing.--With the vent

perform a hot nitrogen purge.

valve still closed, partially fill the container with

enough LOX to permit a sample of the liquid to be

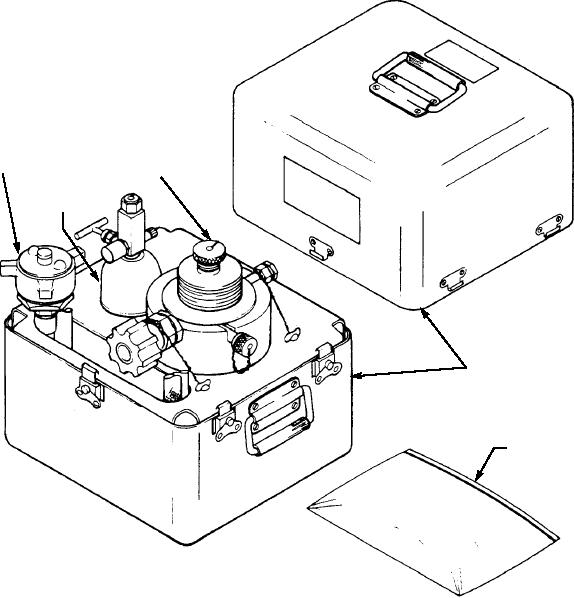

Purging of aircraft converters is done locally. Part

withdrawn for analysis. The sample will be sent to a

of your job as an AS is to maintain the equipment that

"O" level activities use to purge aircraft converters

designated ABO test site, which may or may not be on

with hot nitrogen. This text covers the Aiel

board your station. Results are returned within 1

Corporation's aircraft liquid oxygen system gas

working day of submission.

purging set (fig. 10-11).

Samples are collected in the cryogenic sampler,

This LOX purging set is designed to use gaseous

shown in figure 10-10. Use and maintenance of the

nitrogen or gaseous oxygen for purging (oxygen is

sampler are covered in-depth in Cryogenic Sampler,

used only when nitrogen is not available). In the set, the

Model FCS 2001, AG-115SL-OMP-000.

gas is super heated by an electric heater to 225F 25

If testing indicates that the LOX sample is

for the purging process. The hot gas is forced through

acceptable, the container may be filled and put into

the contaminated unit, where it mixes with the

service. If testing indicates an unacceptable level of

contamination and is vented to the atmosphere.

LO2 AND LN2

HOSE

CHARGING

ASSEMBLIES

MANIFOLD

(TWO HOSES)

ASSEMBLY

CYLINDER

ASSEMBLY

SAMPLE CASE

BASE / COVER

SPARES

KIT

ASf10010

Figure 10-10.--FCS 2001 cryogenic sampler.

10-20