turns of soft steel seizing wire. (See fig. 3-46, view

C.) Place two wraps of seizing wire immediately

above the large seizing, as shown in view D.

Loop and tighten one or two turns of

0.047-inch-diameter copper wire on the end of all

strands, as shown in view D. Using a marlinespike

and tubing, unlay and straighten the strands of the

cable to the top of the seizing. Pull the strands in

toward the center to ensure a good distribution

when the individual wires of each strand are

straightened. (See view D of fig. 3-46.) After all

the strands are straightened, remove the two turns

of seizing previously placed at the top of the large

seizing. (NOTE:

Do NOT remove the large

seizing; this seizing remains in place until pouring

procedures are completed.)

CAUTION

Do NOT use pliers to straighten the

wires; pliers may damage or weaken the

wires.

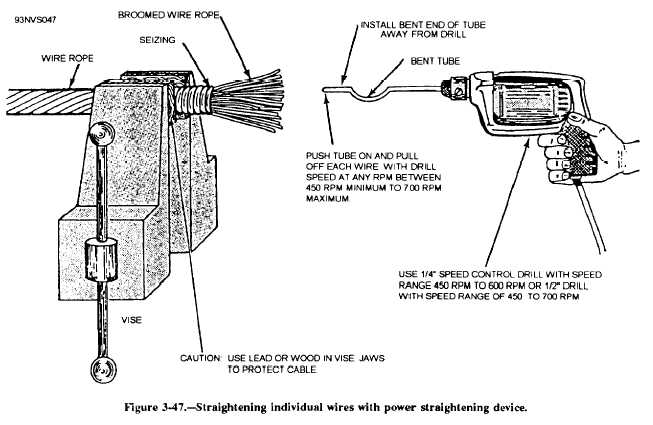

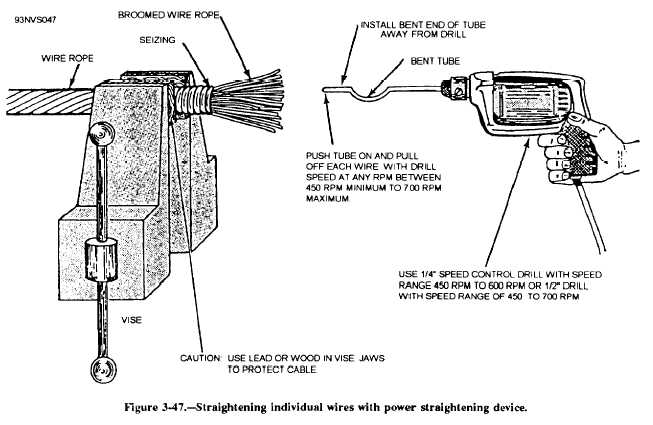

Make certain that the large seizing is tight;

remove the copper wire seizing from one strand at

a time, and straighten the individual wires, using the

power straightening device, shown in figure 3-47.

Repeat the straightening procedure on each

strand, working on one strand at a time, until all the

wires are completely broomed out as shown in

figure 3-47.

Cleaning Wire Rope and Terminal Pouring

The cleaning and preparation of wire rope and

terminals requires the use of chlorinated decreasing

solvents, grit blasting, and the heating and melting

of zinc.

WARNING

Personnel cleaning wire rope and

pouring terminals

must use chemical

respirators and make sure the area is

properly ventilated.

For complete safety

procedures concerning zinc terminal pouring

and wire rope preparation, consult the

current arresting gear NAVAIR operation,

maintenance, and overhaul instructions.

3-52