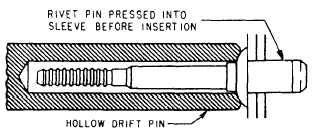

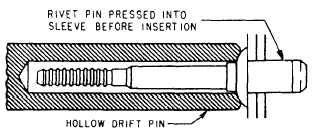

Figure 13-54.—Inserting self-plugging rivet (mechanical lock).

Since no further shank expansion will result, the drill

hole should not be enlarged to provide a free fit of the

already expanded rivet. To insert the rivet, you

should use a hollow drift pin that will accommodate

the rivet pin and the locking collar. See figure 13-54.

This allows a driving force to be exerted on the head

of the rivet. Drive the head into firm contact with the

sheet, and then apply the rivet pull tool in the usual

manner to upset the rivet.

Because of the mechanical lock feature of the pin

and sleeve, the driven rivet is substantially the

mechanical equivalent of a one-piece solid rivet.

Inspection

Visual inspection of the seating of the pin in the

manufactured head is the most reliable means of

inspection. If the proper grip length has been used

and the locking collar and broken end of the pin are

approximately flush with the manufactured head, the

rivet has been properly upset and the lock formed.

Insufficient grip length is indicated by the pin

breaking below the surface of the manufactured head.

Excessive grip length is indicated by the pin breaking

off well above the manufactured head. In either case,

the locking collar might not be properly seated and an

unsatisfactory lock would be formed.

Removal

Removal of this rivet can be accomplished easily

and without damage to the work if you use the

following procedures. See figure 13-55.

1. Shear the lock by driving out the pin with a

tapered steel drift pin not over 3/32-inch diameter at

the small end. If you are working on thin material,

Figure 13-55.—Removing self-plugging rivets (mechanical lock).

13-35