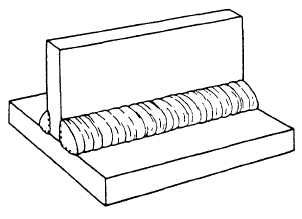

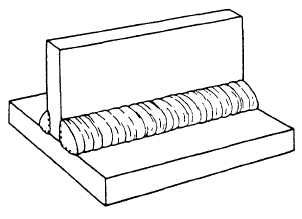

Figure 15-38.—Tee joint-single pass fillet weld.

TEE JOINTS.—Tee joints are used to weld two

plates or sections whose surfaces are located

approximately 90° to each other at the joint. A plain tee

joint welded from both sides is shown in figure 15-38.

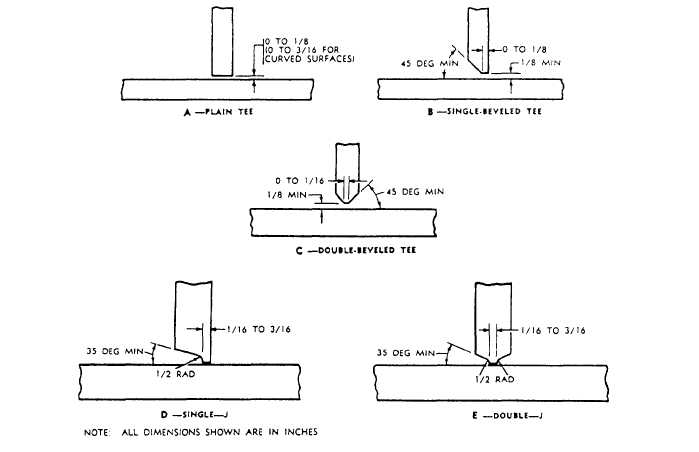

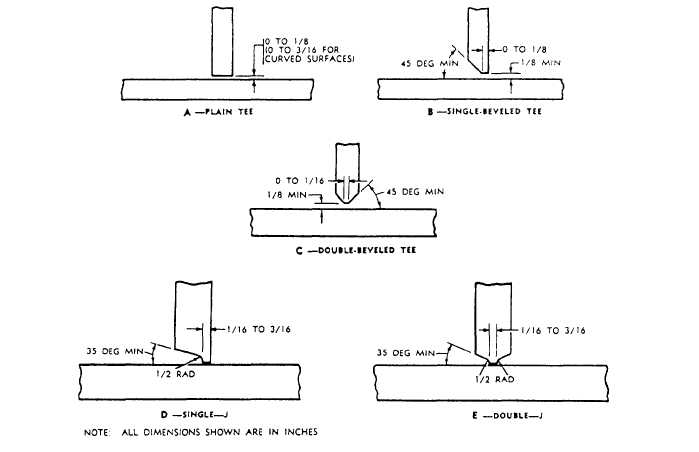

The included angle of bevel in the preparation of tee

joints is approximately half that required for butt joints.

Other edge preparations used in tee joints are shown

in figure 15-39. A plain tee joint, which requires no

preparation other than cleaning the end of the vertical

plate, and the surface of the horizontal plate is shown in

view A of figure 15-39. The single-beveled joint (view

B of fig. 15-39) is used in plates and sections up to 1/2

inch thick. The double-bevel joint (view C of fig. 15-39)

is used on heavy plates that can be welded from both

sides. The single-J joint (view D of fig. 15-39) is used

for welding plates that are 1 inch thick or heavier where

welding is done from one side. The double-J joint (view

E of fig. 15-39) is used for welding very heavy plates

from both sides.

You must take care to ensure penetration into the

root of the weld. This penetration is promoted by root

openings between the ends of the vertical members and

the horizontal surfaces.

LAP JOINTS.—Lap joints are used to join two

overlapping members. A single lap joint, where welding

must be done from one side, is shown in view A of figure

15-40. The double lap joint is welded on both sides and

develops the full strength of the welded members (view

B of fig. 15-40). An offset lap joint (view C of fig. 15-40)

is used where two overlapping plates must be joined and

Figure 15-39.—Edge preparations for tee joint.

15-28