that the cables were tightened evenly, check the

forward sector rig pin hole to see if the rig pin can be

inserted through the sector and into the structure. If

this is not possible, then the cables must be adjusted

by loosening one and tightening the other. This will

maintain the correct tension on the cables, and, at the

same time, rotate the forward sector to the neutral

position. The cable section is properly rigged when it

is possible to insert and remove the forward sector rig

pin easily with the aft sector pin installed and the

cables tightened to the prescribed tension.

The push-pull rod connecting the forward sector

and the bell crank is adjusted to the correct length by

installing a rig pin in the bell crank. Then, the rod

adjustable eye is turned in or out until the rod can be

installed between the sector and bell crank without

binding. At this point three rig pins are in place, and

should remain in place until the control sticks are

rigged to neutral.

When you are positioning the control sticks to

neutral, the rear stick must be adjusted first.

Remember, we are working forward from the elevator

surface. The push-pull rod connecting the bottom of

the rear stick with the bell crank must be adjusted

until the stick center line is the prescribed number of

degrees forward of a vertical reference line. See the

vertical reference line (14) and the center line (15) in

figure 9-26. The vertical reference line is a position

that the center line of the control stick would attain at

a 90-degree angle (19) to the cockpit floor (20).

Adjust the length of the push-pull tube between the

control sticks to position the front control stick to an

angle identical to that of the aft control stick. Then,

remove all three rig pins. This completes the rigging

and adjusting of the control system to neutral. All that

remains is to adjust the stops that limit the fore and aft

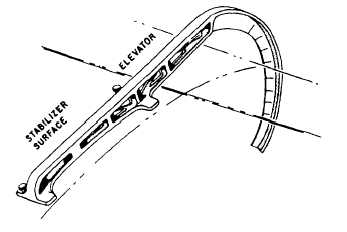

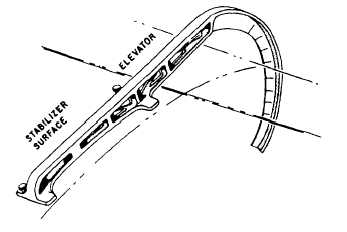

Figure 9-27.—Elevator rigging fixture.

travel of the control sticks, and rig and adjust the

bungee that holds the system in the neutral position.

The stop bolts (2) (fig. 9-26) are located in front

and behind the aft control stick. They are installed so

that the stick hits the stop bolts at the extreme limits of

its travel. The maximum travel of the elevators in

each direction is determined by the manufacturer and

is controlled by the stop bolts. With the rigging

fixture still in place, move the control stick all the way

forward, and adjust the stop until the elevator DOWN

throw conforms to the MIM. Pull the stick all the way

aft, and adjust the aft stop bolt to obtain the correct

elevator UP throw. The stop bolts are safety wired in

place after this adjustment.

The last item to be adjusted in this control system

is the centering bungee.

Connect the bungee and

adjust its rod end so that with the stick against the stop

bolt in the full down elevator position, the bungee is a

minimum of 1/32 of an inch from bottoming. After

this adjustment, the elevators should be held in

neutral (plus or minus the prescribed number of

degrees) by bungee action. If the elevators are too

high, shorten the bungee rod end. If they are too low,

lengthen the bungee.

With the bungee properly

adjusted, tighten the bungee rod end locknut and

safety wire it.

CABLE FABRICATION

Control cables are fabricated mostly of extra

flexible, preformed, corrosion-resistant steel. Control

cables vary from 1/16 to 3/8 inch in diameter. Cables

of 1/8 inch and larger are composed of 7 strands of 19

wires each. Cables 1/16 and 3/32 inch in diameter are

composed of 7 strands of 7 wires each.

Cable-Cutting Equipment

Cutting cables may be accomplished by any

convenient method except an oxyacetylene cutting

torch. The method of cutting usually depends upon

the tools and machines available. If a cable tends to

unravel, the ends may be sweat soldered or wrapped

with a strip of tape prior to cutting.

Small diameter cable may be cut satisfactorily

with a pair of heavy-duty diagonal cutters, side

cutters, or a pair of wire nippers. Best results are

obtained if the cutting jaws are held perpendicular to

the cable during the cutting operation. Cables up to

3/32 of an inch in diameter may be cut in one

operation by this method. Larger cables may require

two or more cuts.

When you cut large diameter

9-33