FORMING SHEET METAL

A sheet metal object made on a brake will

have corners (bends) and sides (flanges). On a

forming machine, it is possible to make an object

without sides.

For example, you can make a

circular object such as a funnel. The forming

machines used in the Navy are usually located at

aircraft intermediate maintenance departments

(AIMDs). The two most common machines are

the slip roll and the rotary.

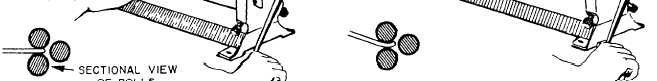

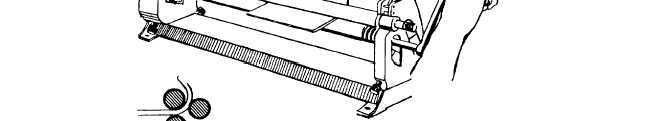

Slip-Roll Forming

Sheet metal can be formed into cylindrical or

conical shapes through the use of the slip-roll

forming machine. Prior to using this machine, you

should consult the manufacturers manual of

operation.

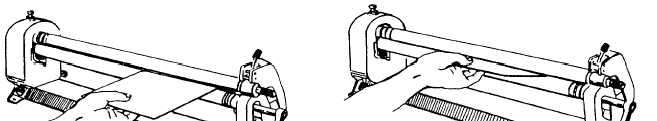

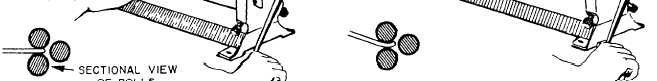

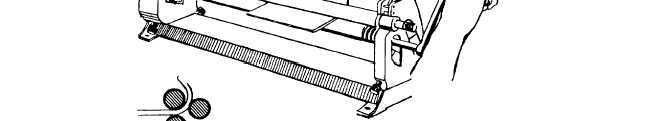

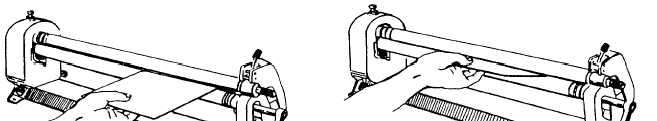

To form a cylinder in the machine, you should use

the following procedures and refer to figure 13-38:

1. Adjust the front rolls so they will grip the

sheet properly.

2. Adjust the rear roll to a height that is less than

enough to form the desired radius of the cylinder.

3. Ensure that all three rolls are parallel. (The

same space exists between any two rollers at each end

of the rollers.)

4. Start the sheet into the space between the two

front rolls. As soon as the front rolls have gripped the

sheet, raise the free end of the sheet slightly.

5. Pass the entire sheet through the rolls. This

forms part of the curve required for the cylinder.

6. Set the rear roll higher to form a shorter

radius.

Figure 13-38.—Forming a cylinder.

13-24