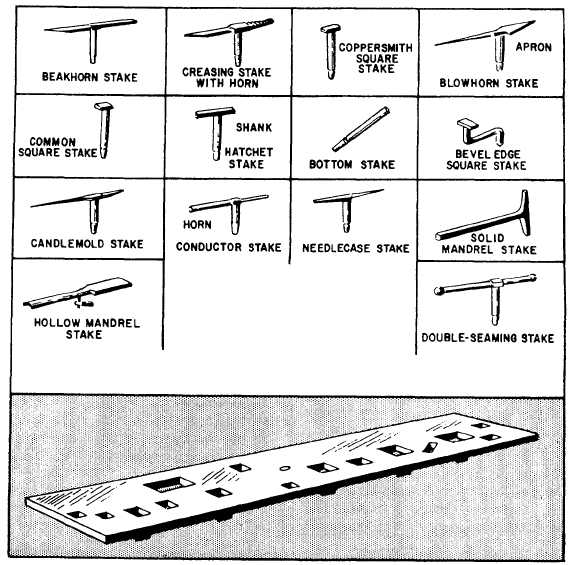

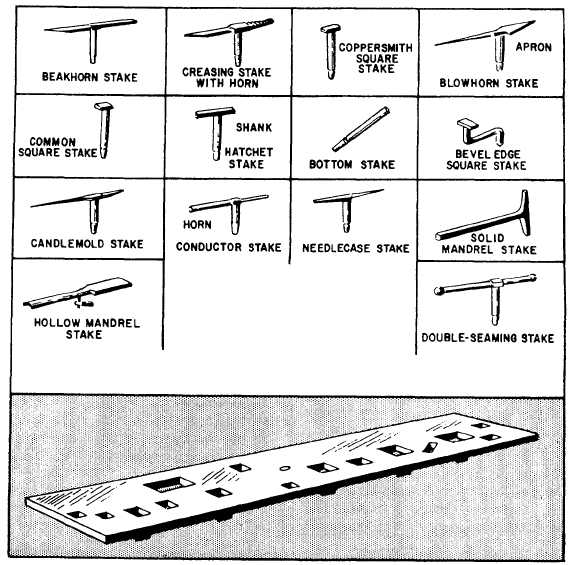

Figure 13-33.—Stakes and stake plate.

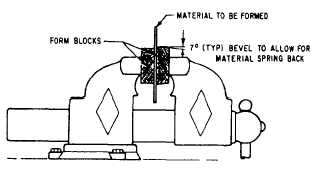

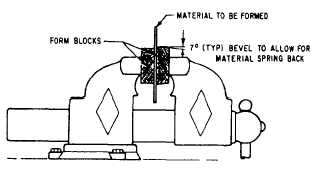

formed by shrinking. Such parts are shaped with the

aid of hardwood or metal form blocks. These blocks

are made in pairs and specifically for the shape of the

part being formed. Each pair conforms to the actual

dimension and contour of the finished article.

You should cut the material to be formed to size,

allowing about one-quarter inch of excess material for

trim. File and smooth the edges of the material to

remove all nicks caused by the cutting tools. This

reduces the possibility of the material cracking at the

edges during the forming operation.

Place the

material between the form blocks and clamp it in a

vise so that the material will not move or shift. Clamp

the work as closely as possible to the particular area

Figure 13-34.—Preparation for straight bend by hand.

being formed to prevent strain on the form block and

to keep the material from slipping.

13-21