The other type of system in current use has its

own compressor and other equipment necessary for

maintaining an adequate supply of compressed air

during flight. Provision for ground charging this type

of system is also provided. In addition to a

compressor, the components in this type of system

usually include a filter, a pressure regulator, a

moisture separator, a relief valve, a chemical drier,

and storage cylinder(s).

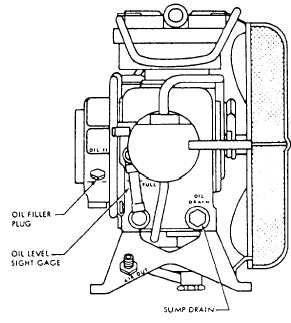

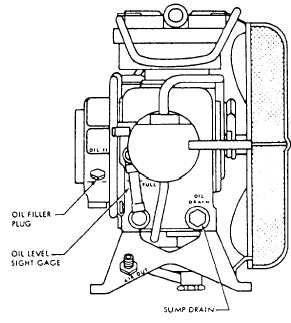

AIR COMPRESSORS.—A typical air com-

pressor is shown in figure 7-43. An installation of this

type receives its supply of air from the compressor

section of the aircraft engine.

This air is then

compressed further to the required pressure for

operating the system. Compressors of this type are

capable of maintaining up to and above 3,000 psi

pressure during flight.

On some aircraft, the compressor is operated by

an electric motor. On others, a hydraulic motor is

used to drive the compressor. Compressors must be

serviced with oil periodically, as outlined in the

aircraft MIM. An oil level sight gauge is provided on

the compressor (fig. 7-43).

AIR FILTERS.—An air filter is usually located

in the line leading into the system compressor.

Additional filters may be located at various points in

the system lines to remove any foreign matter that

may enter the system.

Figure 7-43.—Air compressor.

Like hydraulic filters, air filters have a removable

element and a built-in relief valve. The relief valve is

designed to open and bypass the air supply around the

filter element should the element become clogged.

Some air filters are equipped with the micronic-type

element, which must be replaced periodically. Others

have the screen mesh type, which requires periodic

cleaning. The latter type may be reinstalled after

cleaning and drying.

AIR PRESSURE REGULATORS.—A pressure

regulator is generally located in the line between the

engine compressor and the pneumatic system

compressor; however, it may be incorporated within

the system moisture separator. Its purpose is to

regulate the pressure of the supply air before it enters

the system compressor. The pressure regulator

maintains a stable outlet pressure regardless of the

inlet pressure.

MOISTURE SEPARATORS.—The moisture

separator in a pneumatic system is always located

downstream of the compressor. Its purpose is to

remove any moisture caused by the compressor. A

complete moisture separator consists of a reservoir, a

pressure switch, a dump valve, and a check valve, and

it may also include a regulator and a relief valve. The

dump valve is energized and de-energized by the

pressure switch. When de-energized, it completely

purges the separator reservoir and lines up to the

compressor.

The check valve protects the system

against pressure loss during the dumping cycle and

prevents reverse flow through the separator.

RELIEF VALVES.—A relief valve is

incorporated in a pneumatic system to protect the

system from overpressurization. Overpressurization

is generally caused by thermal expansion (heat).

Relief valves are generally adjusted to open and close

at pressures slightly above normal system operating

pressure.

For example, in a system designed to

operate at 3,000 psi, the relief valve might be set to

open at 3,750 psi and reseat at 3,250 psi.

CHEMICAL DRIERS.—Chemical driers are

incorporated at various locations in a pneumatic

system. Their purpose is to absorb any moisture that

may collect in the lines and other parts of the system.

Each drier contains a cartridge, which should be

blue in color. If otherwise noted, the cartridge is to be

considered contaminated with moisture and should be

replaced.

STORAGE CYLINDERS.—Pneumatic storage

cylinders (bottles) are made of steel and maybe either

7-44